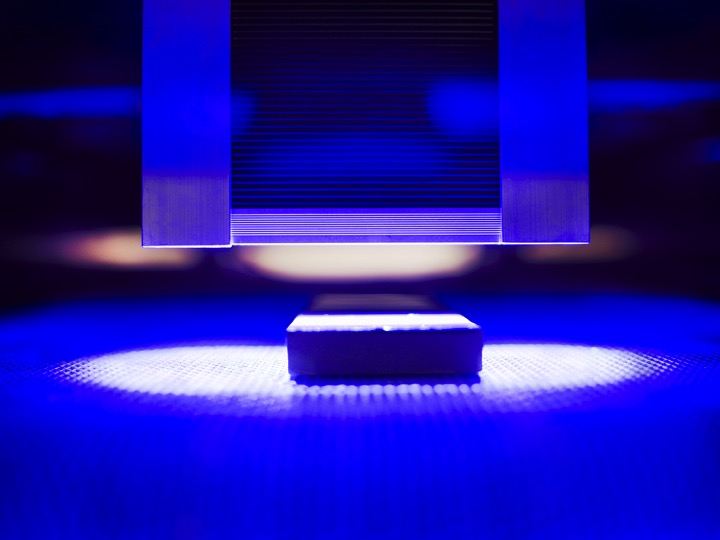

Next generation LED curing technology from Sherwin-Williams provides energy savings and outstanding results

Today, Sherwin-Williams is announcing a new LED innovation aimed at manufacturers within the wood finishing industry – Full Curing LED. This breakthrough technology makes it possible to implement LED throughout the entire curing line, opening up for even more energy savings and quality improvements than before.

“We´ve been working towards a solution like this since we first introduced LED curing in 2012. However, there was always a problem with unwanted yellowing effects due to difficulties with the topcoat. For a while, it seemed that a combination of LED and UV lamps was the only way to go, but we pushed forward and the R&D division finally came up with the right formula to make it work. It´s now possible to use LED lamps in every step of the curing process, eliminating the need for conventional UV lamps altogether. This will allow for a much more effective production”, says Martin Andersson, Product Manager at Sherwin-Williams.

Due to the low curing temperatures of LED, it´s possible to coat materials such as pine and other resinous woods with significantly lower reject rates. The LED lamps also last thousands of hours, which decrease the overall maintenance costs compared to using conventional UV lamps, and without a warm up cycle there is less down time. Additionally, LED lamps do not produce high temperatures or harmful ozone, which reduces environmental impact.

Several companies worldwide have already implemented LED in their curing lines, and the interest is booming:

“Our participation at the LIGNA exhibition this year really reinforced our belief that the market is ready; LED was everywhere. Since it´s so trending and we’re already in discussions with several major clients on implementing LED technology, it´s only logical that we take this last step to facilitate a 100% LED curing line. Since we conducted this as an internal project without any client involvement, we now have to test Full Curing LED together with our machine suppliers and present it to our current LED customers. We´re very excited about this”, says Martin Andersson.

Come and meet us and hear more abour Full LED at Bürkle Technology Days September 22-25 September. Read more here

For more information, please contact:

Press contact

Eric Uggla

Mobile: +46 704 15 15 25

Email: eric.uggla@sherwin.com

Sherwin-Williams

Marie-Louise Eklund, Brand Manager EMEA

Mobile: +46 70 575 62 24

Email: marie-louise.eklund@sherwin.com

About Sherwin-Williams Product Finishes

The Sherwin-Williams Company (SHW), through its Product Finishes Division, is an industrial coatings leader that delivers local finishing solutions on a global scale to OEMs and tier suppliers. Comprised of coatings professionals dedicated to providing unparalleled customer support, Sherwin-Williams brings value to the finishing process through solutions like on-site technical assistance, customized products, colour and design services, and process improvement expertise. With innovative liquid and powder coating technologies to protect wood, metal and plastic, as well as finishing equipment and supplies needed for coatings application, Sherwin-Williams utilizes an infrastructure spanning six continents to provide better finishing solutions for manufacturers. For a Better Finish. Ask Sherwin-Williams™.

About The Sherwin-Williams Company

Sherwin-Williams is a global leader in the development, manufacture and sale of coatings and related products with more than 39,700 employees and business in 120 countries. The company goes to market through more than 4000 company-operated paint stores, automotive retailers, and industrial distributors. With annual sales of $11 billion, it is the largest coatings manufacturer in the United States, and the third largest world-wide.

Tags: