SSAB towards the internet of materials with SSAB SmartSteel

What if the steel in your car, your house or the cruise ship taking you to your holiday destination was equipped with a key to information describing its entire history? Every party in the production chain could add to and utilize this information, and ultimately the end users - companies or consumers - could rest assured of the quality, safety and sustainability of their product. How would that affect our cities and the way we produce and use the essentials of a modern society?

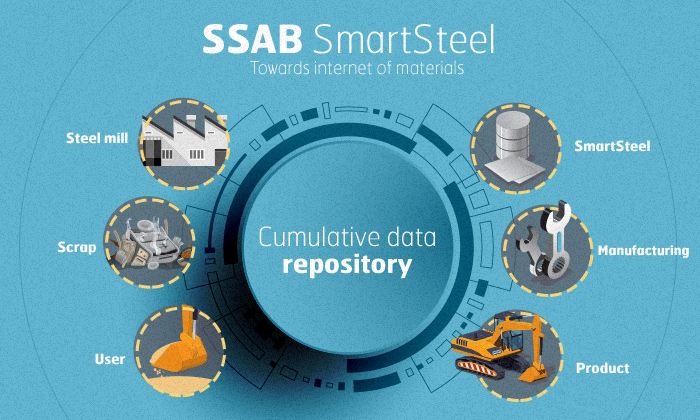

SSAB has recently finalized an R&D project that explores the concept of SSAB SmartSteel, a digital platform that enables the steel to be loaded with knowledge. A unique identity code in the steel plate connecting the plate and information provides customers and their machinery with appropriate data and instructions to help them to select and use SSAB steels, regardless of their application. The idea is to share the expert knowledge in steel that SSAB stands for.

“Our vision is a platform built on cloud-based data that contains instructions for different stakeholders in the value chain on how to use our steel,” explains Eva Petursson, Head of R&D at SSAB and continues that “by accessing and adding data on the platform, our customers would be able to make optimal use of the steel and avoid costly and time-consuming failures and misuse. In simple terms, data bring material handling competence where it is needed.”

In the pilot R&D project, SSAB, under project leader Seija Junno, worked together with partners including Meyer Turku, Cajo Technologies, Aalto University, VTT Technical Research Centre of Finland Ltd, DIMECC (Digital, Internet, Materials & Engineering Co-Creation) and Academy of Finland’s Strategic Research Council. The first results have been very positive in the area of identifying the plates and finding the corresponding data automatically.

“We are looking for ways to create sustainability‐based added value for our customers, e.g. by telling the carbon footprint or energy consumption during the whole lifecycle of the ship. If steel could provide all the data accumulated during the manufacturing and transportation chain, it would help us significantly and would be the first step towards transparent value chains in our field,” says Jaana Hänninen, Environmental Manager at the Meyer Turku shipyard.

Open invitation to customers and partners

SSAB is now ready to further explore the possibilities of the SSAB SmartSteel platform together with more customers and partners and in this respect openly invites all interested customers, process equipment manufacturers and other actors to join the development work. Rapid trials will enable the idea to take shape and grow clearer.

“We recognize that the only way to fully develop this idea is to co-create with other companies. We think working together is smart - everyone involved wins. We are only just beginning to understand how this can affect everyone in the value chain and ultimately the society we live in,” says Eva Petursson.

Contacts for interested customers and partners:

Eva Petursson, Head of R&D at SSAB, eva.petursson@ssab.com

Seija Junno, Director, Business model development at SSAB, seija.junno@ssab.com

Media information, please contact:

Viktoria Karsberg, Head of Corporate Communications, viktoria.karsberg@ssab.com,

phone: +46 72 233 5288

SSAB is a Nordic and US-based steel company. SSAB offers value added products and services developed in close cooperation with its customers to create a stronger, lighter and more sustainable world. SSAB has employees in over 50 countries. SSAB has production facilities in Sweden, Finland and the US. SSAB is listed on the Nasdaq OMX Nordic Exchange in Stockholm and has a secondary listing on the Nasdaq OMX in Helsinki. www.ssab.com.

Tags: