Magnetic Ring Encoder Offers New Benefits To Large Rotating Machinery

- Leine & Linde's MRI 2000 Rotary Encoder -

Schaumburg, IL - (October 2014) – The Leine & Linde MRI 2000 rotary encoder is designed to provide feedback solutions for large rotating machinery, typically found in the Construction, Pulp & Paper, Oil & Gas, Wind and Marine industries. Introduced two years ago, this encoder has now received significant performance upgrades.

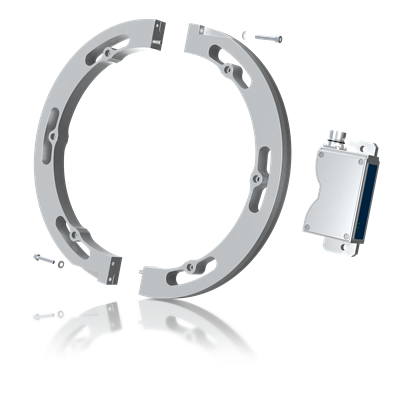

The MRI ring encoder is segmented into pieces, something that facilitates simple commissioning and service and is of particular benefit on large rotating machinery. As a ring is often mounted on a shaft between other parts in the machinery, it can be difficult to access it, both when first mounting it and when performing service. With a segmented ring, the pieces can be mounted from two sides of the shaft and screwed together. The segments also make handling easier when transporting and storing the ring.

Fixing the ring to the shaft can be made through flange mounting with axial screws or by Leine & Linde's ClampFit solution for simplified commissioning. With ClampFit, the ring segments are screwed together in a way that automatically tightens the ring around the mating shaft. This enables fixing to large cylindrical shaft without any flange surface considerations and without the need for stub shafts.

In this most recent evolution of the product, the ring is now also available with an alternative magnetic structure, enabling relaxed tolerances for the sensor pickup mounting. Radial gap tolerances have been doubled, allowing up to 6mm between the sensing head and the ring surface. In addition, frequency response of the pickup has been doubled as well, providing the opportunity for higher shaft speeds.

Once installed, LED outputs verify power and signal quality giving the operator immediate verification of system health. Options include overvoltage protection and a programmable reference mark to simplify initialization of the motion control system

The MRI 2000 offers TTL, HTL and RS-422 outputs for standard applications. High Current HTL and the Opto-link fiber-optic outputs are also available which have been specially designed for long distance transmission such as those found in cranes and wind turbines.

For more information, contact product manager Bob Setbacken at HEIDENHAIN at 805-562-1160 or e-mail at bsetbacken@heidenhain.com , or write to HEIDENHAIN Corporation, 333 E. State Parkway, Schaumburg, IL 60173.

Leine & Linde is based in Sweden with exclusive North American distribution through HEIDENHAIN Corporation in Schaumburg, IL. Leine & Linde is well known for offering high quality, heavy duty encoders of both the incremental and absolute types, are noted for their product robustness and design to cope with the harshest of environments, such as those with high vibration, dirt and cold temperatures. These heavy, severe duty encoders are suited for drive and measurement applications and are often found in industries such as pulp and paper, forest and wood processing, agriculture, aggregate and mining equipment.

Tags: