Zuken reduces manufacturing costs with latest E³.series release

E³.series 2014A available now

1 July 2014 – Munich, Germany and Westford, MA, USA – Zuken announces manufacturing cost reductions through enhanced electrical design. The latest version of E³.series – Zuken’s industry-leading electrical and fluid CAD software – contains integration with B&R Automation Studio, data export for drilling and milling machines, XVL output for Lattice viewer, and enhanced support for Komax and eCl@ss. Support for harness families and harness derivatives within a single design offer time-saving benefits for the transportation sector.

Joachim Frank, Director of E³.series business, said: “Today, workers often need to manually interpret manufacturing documentation in order to assemble control systems. Now, with automatically-produced wires and step-by-step routing instructions, the need to read and interpret these documents is removed. This gives companies the option to retain assembly in-house, thereby reducing manufacturing outsourcing costs.”

Manufacturing process cost reductions

E³.series 2014A adds new and enhanced manufacturing features to reduce manufacturing costs.

- Manufacturing output for drilling and milling machines is automatically-produced by E³.CutOut. This uses drill hole and cutout definitions from the E³.series library to export data such as outlines, cut outs, drill holes and restrictions in standardized DXF format. Machining preparation time is reduced and accuracy increased.

- With enhanced Komax support, automatically-produced wire bundles mean assembly teams do not need to create and cut wires manually by referring to schematic drawings. Estimates show this leads to a reduction in assembly time of more than 50%.

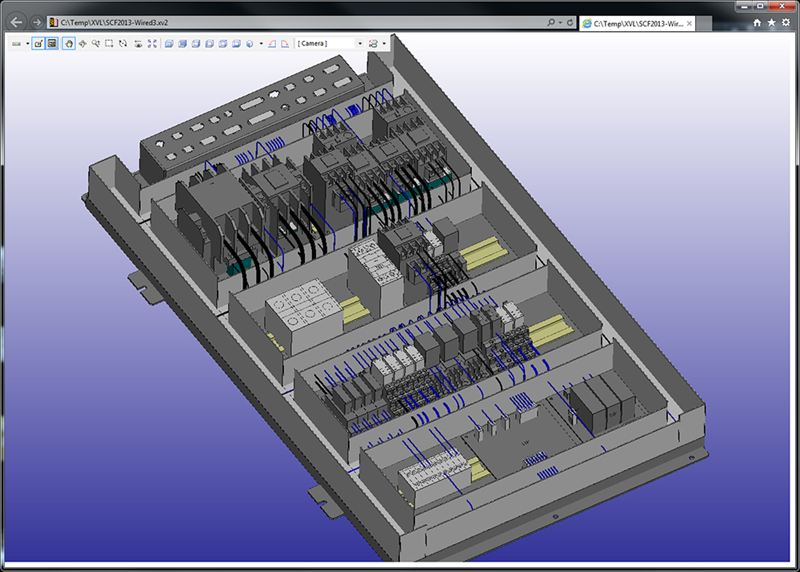

- Lattice viewer support includes XVL format. This enables 3D panel viewing and animation in XVL Player from Lattice. With XVL Studio, users can generate animated, step-by-step assembly movies making the manufacturing process clearer and faster.

Enhanced automation

The new E³.PLC Bridge provides easy-to-use bidirectional PLC data exchange in formats such as B&R Automation Studio – widely-used in the machinery sector. B&R Automation Studio allows the controller, drive, communication and visualization to be configured in one environment, reducing integration time and maintenance costs. With bidirectional transfer of data, interaction between electrical design and software development teams is accelerated and data quality improved.

Advanced component data

Zuken’s new eCl@ss Advanced tool enables efficient download and read-in of electrical component data from the eCl@ss format into E³.series libraries. eCl@ss is the standard for classification and description of products for 39,000 product classes and 16,000 properties spanning all disciplines. eCl@ss Advanced, provided by component manufacturers, contains electrical component data to quickly create library components that are up-to-date and accurate.

Many options, one design

In E³.cable and E³.formboard, harness families and harness derivatives are supported within a single design, eliminating the need to handle different options of the same wire. Different wire lengths requiring specific properties can be handled within a single design and viewed and managed with fewer steps.

For more information see www.zuken.com/e3series

- ends –

For a downloadable Word document and press images visit the press kits area of the press center www.zuken.com/presskits.

Words = 452

Captions

Image: Zuken-Z0413-PLC-Bridge-Update1.jpg

Caption: E³.PLC Bridge provides an easy-to-use bidirectional interface to automate PLC data exchange

Image: Zuken-Z0413-XVL-Viewer2.jpg

Caption: E³.series panel design shown in Lattice XVL Viewer

Image: Zuken-Z0413-Options-Wires3.jpg

Caption: All optional wires and all possible routing paths are created automatically by E³.series

For more information contact your local PR person:

Americas

Amy Clements, Zuken USA Inc., 238 Littleton RD, STE 100, Westford, MA 01886

Tel: 1 972-691-3284

E-mail: amy.clements@zuken.com

Twitter: @ZukenAmericas

Northern & Southern Europe

Sally Wilkes, Zuken Ltd., 1500 Aztec West, Almondsbury, Bristol, BS32 4RF, UK

Tel: 44 (0)1454 207800

E-mail: sally.wilkes@zuken.com

Twitter: @ZukenUK_SCAN

Poland

Dionne Hayman, Zuken Ltd., 1500 Aztec West, Almondsbury, Bristol, BS32 4RF, UK

Tel: 44 7980 797040

E-mail: dionne.hayman@zuken.com

Twitter: @ZukenUK_SCAN

Central Europe

Klaus Wiedemann, Zuken GmbH, Am Söldnermoos 17, 85399 Hallbergmoos, Deutschland

Tel.: 49 89 607696-58

E-mail: Klaus.Wiedemann@zuken.com

Twitter: @ZukenCentralEur

About Zuken

Zuken is a global provider of leading-edge software and consulting services for electrical and electronic design and manufacturing. Founded in 1976, Zuken has the longest track record of technological innovation and financial stability in the electronic design automation (EDA) software industry. The company’s extensive experience, technological expertise and agility, combine to create world-class software solutions. Zuken’s transparent working practices and integrity in all aspects of business produce long-lasting and successful customer partnerships that make Zuken a reliable long-term business partner.

Zuken is focused on being a long-term innovation and growth partner. The security of choosing Zuken is further reinforced by the company’s people—the foundation of Zuken’s success. Coming from a wide range of industry sectors, specializing in many different disciplines and advanced technologies, Zuken’s people relate to and understand each company’s unique requirements. For more information about the company and its products, visit www.zuken.com.

Tags: