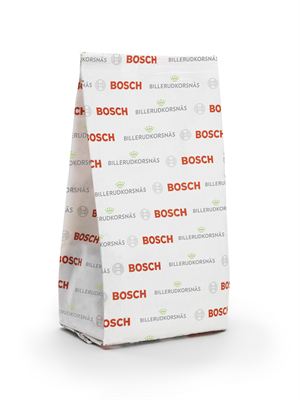

Introducing a revolution: The sustainable dust-tight Sealed Paper Packaging for dry foods

A clean environment, as well as clean shelves and supply chains, without compromising material strength and stability. It is now possible to replace conventional packaging for dry foods with the first dust-tight sealed all-paper packaging produced on vertical form, fill and seal (VFFS) lines.

BillerudKorsnäs continues in its quest to solve the packaging challenges of the future. Together with Bosch Packaging Technology, the companies are now launching the world’s first Sealed Paper Packaging. This is intended to enable brand owners to reduce their environmental footprints and enhance customer experiences by choosing paper packaging over plastic. This revolutionary solution is perfect for dry foods and keeps both shelves and the environment clean.

“We are committed to challenging conventional packaging and this is a natural step – which will be followed by many more such steps,” says Johan Nellbeck, SVP Packaging Paper at BillerudKorsnäs. “By working together with machine suppliers on a broad range of issues, we can explore and unlock the potential of our materials in order to find new solutions to meet packaging needs.

The key to success in this particular case has been a fruitful partnership with Bosch. Along with our Axello® ZAP paper, which has been developed specifically to be strong and resilient enough for use on the Bosch PME ZAP, the first VFFS solution with ZAP-Module, and our expertise in packaging materials, the collaboration has formed the basis for this innovation.

“This unique concept would not have been implemented without the collaborative effort of both companies. Together we developed a truly unique solution,” says Joachim Dittrich, head of product division Liquid Food at Bosch Packaging Technology and responsible for the VFFS ZAP portfolio.”

Apart from being all paper and therefore renewable, recyclable, and biodegradable, the new Sealed Paper Packaging is also dust-tight and insect-proof. This keeps food particles in and contamination out during transport and while on the shelf, thereby resulting in a cleaner environment and less food waste. The success of the product is based on the quality of the paper in combination with the technology to reliably seal the packaging.

The market for this solution is, of course, huge. It is perfect for a broad range of products, such as pasta, oats, flour, rice, muesli and sugar, not to mention the wide range of non-food items that are currently packed in fossil-based packaging. A recent LCA study confirmed that the Axello ZAP bag results in a 65% lower carbon footprint than a corresponding plastic bag (source: Life Cycle Assessment, Report U5052, IVL, 2015).

For further information, please contact:

Patrik Bosander, Business Development Director Packaging Paper, +46 702135990, patrik.bosander@billerudkorsnas.com

Ole Paulussen, Sales Director System Sales, Bag Solutions, Packaging Paper, +49 170 9211013, ole.paulussen@billerudkorsnas.com

Marcus Velezmoro, Head of Sales Package Makers at Bosch Packaging Technology, +49 711 811-57850, marcus.velezmoro@bosch.com

BillerudKorsnäs provides packaging materials and -solutions that challenge conventional packaging for a sustainable future. We are a world leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4 200 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Tags: