Hi-Tech Automation showcase integration of six axes FANUC robot with latest ROBOSHOT injection moulding machine at PDM13 Exhibition

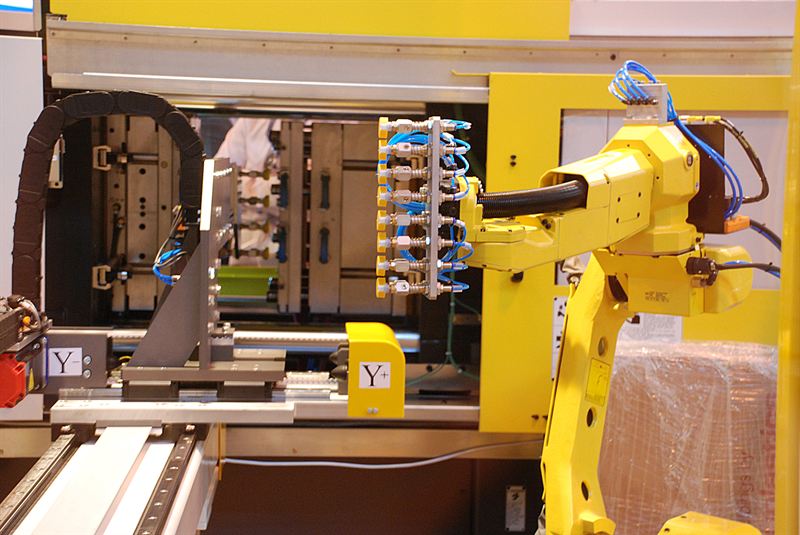

Hi-Tech Automation will showcase the integration of robotic automation with a high speed load/unloader and an injection moulding machine at the PDM13 Exhibition, Telford, 18 -19 June. A strategic partner of FANUC UK, Hi-Tech Automation will demonstrate the flexibility offered by a six axes FANUC M-10iA robot, used in conjunction with a Hi-Tech manufactured high-speed side loader.

The demonstration will illustrate how short cycle times can be maintained even when loading inserts or labels and, Integrated with FANUC’s new ROBOSHOT S100-iA moulding machine, Hi-Tech will demonstrate the performance and productivity gains achievable through FANUC’s common control platform.

Making its first UK appearance, the FANUC ROBOSHOT S100-iA all electric moulding machine uses FANUC’s latest standard servo control system providing energy saving features such as regenerated power from decelerating motors; high levels of control for superior moulding repeatability and shorter cycle times enabled through high-speed and accurate simultaneous motion control.

Image: Fa-148-01 FANUC M-10ia unloading Hi-Tech Automation side-loader arm and a ROBOSHOT moulding machine

Image: Fa-148-02 Hi-Tech Automation side-loader robot

Ref: Fa-148-A

Issue date: April 2013

Photography and video:

Contact David Wickham davidw@jonoliver.com for digital images

Issued by:

Jon Oliver Communication Ltd.

+44-(0)1902-757115 email: davidw@jonoliver.com

Further information:

Hi-Tech Automation Limited

Gary Probert, Director

e-mail: gary@hitechautomation.com

tel: +44 (0)1536 312131

Website: www.hitechautomation.com www.fanuc.eu

Notes to editors:

Hi‐Tech Automation has been operating for 16 years and was set‐up specifically to deliver robotic automation solutions for the plastics industry. It has a strong understanding of the issues faced by injection moulding businesses particularly when considering commitment of capital expenditure on automation systems.

To ensure quality is built in to its robots Hi-Tech has developed a strong partnership with the World’s leading robotics company FANUC.

FANUC UK provides industrial automation solutions from the supply of CNC controllers, robots, drilling machines, EDM and injection moulding machines through to the complete integration of factory automation systems.

Providing a single customer support portal for its three core businesses, FANUC UK comprises FA – CNC Controllers, motors and drives, Robotics – industrial robots and systems, Robomachines – EDM, Injection Moulding, drilling machines.

FANUC employs 6,500 people world-wide. Based at the foot of Mt Fuji, near Lake Yamanaka, FANUC's factory uses over 2,000 FANUC robots to support a monthly production capacity of 30,000 CNC controllers, 5,000 robots, 250,000 servo and spindle motors and 5,000 robomachines and 250 CO2 lasers.

Tags: