Hi-Tech Automation shows versatile machine-build options and integration with common platform

Hall 13 Stand E75 EMO Hannover 2013

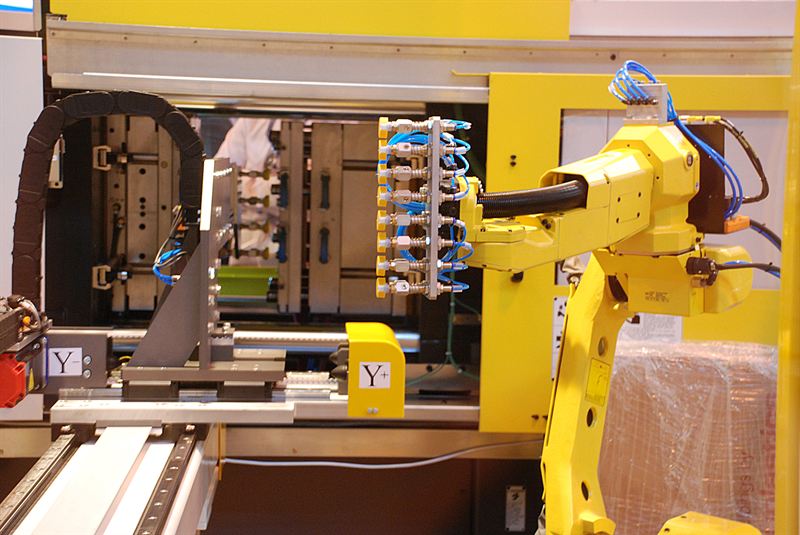

Using FANUC's common control and drive platform, together with proprietary machines and robots, Hi-Tech Automation will showcase the versatility it provides to users of its design and integration services.

Focusing on machine load and unload, Hi-Tech Automation will feature its CR Machine Tending Robot with an all electric FANUC S-2000i injection moulding machine and two robot machine loading systems featuring the newly introduced FANUC ROBODRILL α-D21 Series machining centre.

Developed specifically for high speed handling, the Hi-Tech Automation CR Range is ideally suited to injection moulding and machine tending applications. Using FANUC's intelligent Power Motion i-A control platform and CNC drives, it provides high levels of accuracy with straight line and linear interpolation as standard. Application specific functions, provided through the easy to use i-Pendant, include platen following to reduce mould open time, and collision avoidance to guard against operator error during tool set-up.

Loading and unloading a cylinder head into a FANUC ROBODRILL α-D21 Series machining centre will be an R-1000 i-A robot, FANUC's 100Kgs payload workhorse ideally suited where fast and accurate handling and positioning of product is required. The system will also illustrate FANUC's 2D vision using standard integrated vision software.

Also integrated to a ROBODRILL α-D21 Series machining centre will be a LR Mate-200iD robot loading and unloading small components. Designed for 24/7 high duty cycles, the ROBODRILL and LR Mate combination is ideally suited for batch production where the system can effectively be operated unmanned.

A strategic partner of FANUC, Hi-Tech Automation brings in-depth application-specific experience to the partnership, allowing customers to benefit from proven integration of their high value automation assets.

Ref: Fa-159-A

Issue date: Aug 2013

Photography and video:

Contact David Wickham davidw@jonoliver.com for digital images

Issued by:

Jon Oliver Communication Ltd.

+44-(0)1902-757115 email: davidw@jonoliver.com

Further information:

Hi-Tech Automation Limited

Gary Probert, Director

e-mail: gary@hitechautomation.com

tel: +44 (0)1536 312131

Websites: www.hitechautomation.com and www.fanuc.eu

Notes to editors:

Hi‐Tech Automation has been operating for 16 years and was set‐up specifically to deliver robotic automation solutions for the plastics industry. It has a strong understanding of the issues faced by injection moulding businesses particularly when considering commitment of capital expenditure on automation systems.

To ensure quality is built in to its robots Hi-Tech has developed a strong partnership with the World’s leading automation company FANUC.

FANUC UK provides industrial automation solutions from the supply of CNC controllers, robots, drilling machines, EDM and injection moulding machines through to the complete integration of factory automation systems.

Providing a single customer support portal for its three core businesses, FANUC UK comprises FA – CNC Controllers, motors and drives, Robotics – industrial robots and systems, Robomachines – EDM, Injection Moulding, drilling machines.

FANUC employs 6,500 people world-wide. Based at the foot of Mt Fuji, near Lake Yamanaka, FANUC's factory uses over 2,000 FANUC robots to support a monthly production capacity of 30,000 CNC controllers, 5,000 robots, 250,000 servo and spindle motors and 5,000 robomachines and 250 CO2 lasers.

Tags: