Packaging sector debut for new Kawasaki Delta robot at PPMA Show

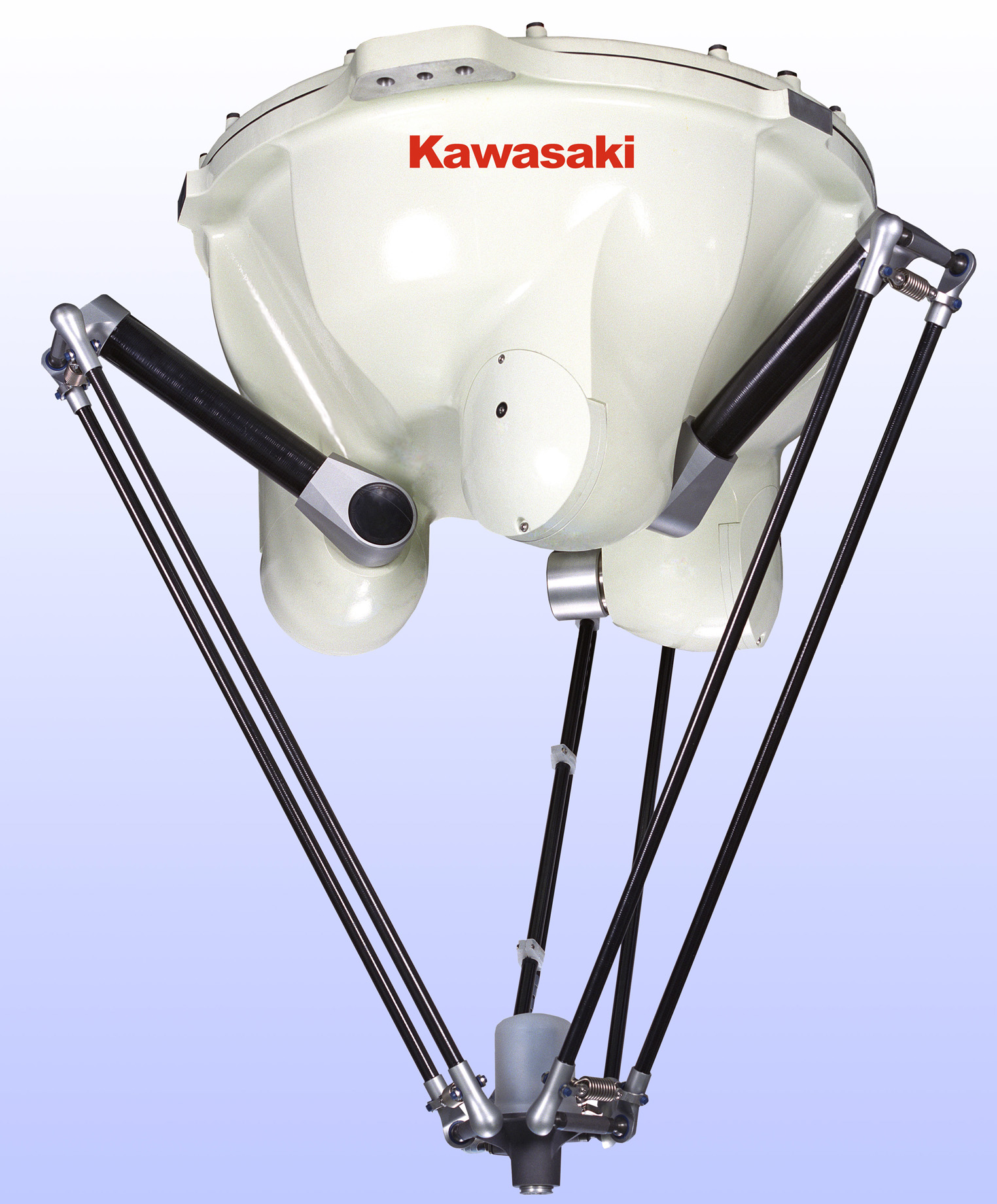

Kawasaki Robotics will debut its first Delta arm robot to the packaging industry at this year’s PPMA Show. Designed for high reliability and ease of maintenance, the new Y Series claims to be best in class for speed and repeatability.

Integrated with a vision system, the new Y Series will illustrate ultra high speed pick and place tasks while maintaining smooth motion control and accurate repeatability. With a maximum payload of 3kg, the Kawasaki Y Series performs the standard industry TAC test of 25/305/25 in only 0.45 seconds. With a maximum payload of 1kg, the TAC test time lowers to just 0.27 seconds.

Accuracy is also a class leading feature of the Y Series with positional and angular repeatability of +/- 0.1mm. An optional fifth axis further enhances placement capabilities.

With high reliability in mind, the Y Series design avoids using a centre shaft for rotational movement by having a wrist mounted motor. This design further reduces exposed components and potential contamination traps, simplifying cleaning and maintenance tasks. The new robot also has a large work envelope of 1,300mm on horizontal and 500mm on vertical movement.

Making the Y Series easier to integrate and increasing its performance, it is supplied with Kawasaki’s latest E-Controller. The E-Controller range offers faster processing, increased memory, higher resolution encoding, increased communications options and additional teach pendant functionality.

Food grade grease and oil is standard on the Y Series, assuring hygiene standards are kept to a maximum. In addition to food grade grease and oil, it has been designed for wash down with abrasive acid/alkaline cleaners, making it the ideal choice for installation in to food and pharmaceutical applications.

Ref: Ka-008-A Issue date: July 2011

Photography and graphics:

Contact: Katiel@jonoliver.com for high resolution image file.

Issued by:

Katie Lees, Jon Oliver Communication Ltd. +44-(0)1902-757115

Further information:

Jim Carr, UK Sales and Marketing Manager, Kawasaki Robotics UK Ltd

Units 6 & 7, Easter Court, Europa Boulevard, Warrington WA5 7ZB

Tel +44 (0)1925 713000 email: sales@kawasakirobotuk.com

Visit our web site: www.kawasakirobot.co.uk

Notes to editors:

Kawasaki Robotics (UK) Ltd is theUK robotics division of Kawasaki Heavy Industries Japan.

Based inWarrington, Kawasaki Robotics (UK) Ltd occupies a 15,000Sq.Ft.Building. Its location provides easy access to the main motorway network and is at the centre of its customer base.

The facility centralises all the sales and customer support operations, with areas for customer demonstrations, training, robot test and integration and a large area for stock machines. Over 1,800 machines are now operating in a wide range of industries and applications throughout theUK.

Operating through a network of system partners, automation integrators and also supplying direct to end users, Kawasaki Robotics (UK) Ltd offers experience in the widest range of industry sectors.

Kawasaki Heavy Industries introduced its first industrial robot into the Japanese domestic market in 1969 and since then has developed into a world leader in the manufacture of industrial robots. Renowned world-wide for quality and technology in all its engineering systems and products, this philosophy is continued throughout the Kawasaki Robotics divisions.

Tags: