Robot 'first timer' meets exponential growth in marine pump demand

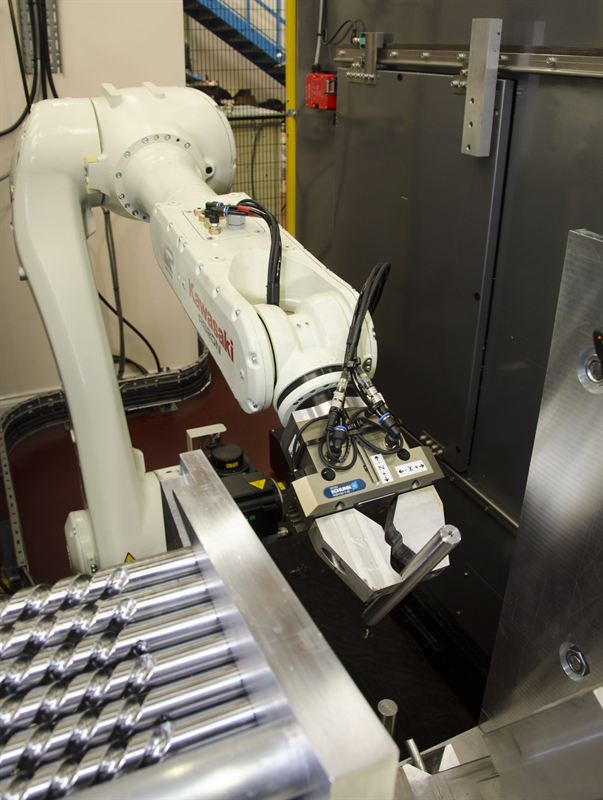

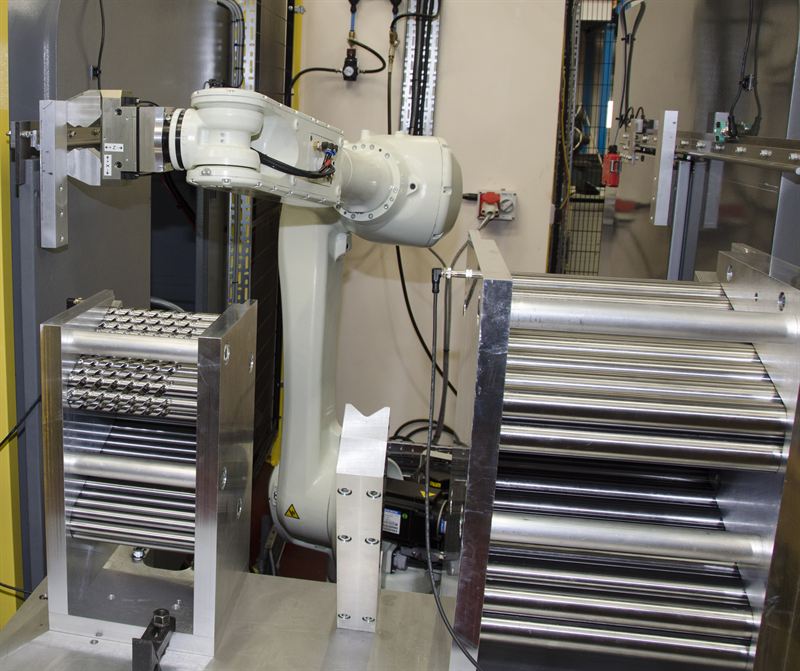

The economic viability of its new marine pump and legislation on the use of heavy fuels in international waters has increased production demand exponentially for Separator Spares International (UK) Ltd. To maintain its competitiveness and meet demand the Isle of Wight based manufacturer has installed its first robot, a Kawasaki R Series, to load and unload parts from two 4 axes twin spindle milling machines.

Supplying large ships, SSI specialises in the manufacture and supply of spare parts for pumps and other essential components. Evolving from a supplier of 'O' rings to a manufacturer of high precision pumps, made to its own design, has given SSI a strong reputation for highly efficient products at competitive prices.

"We used to buy all our rotors in while we were developing our own designs and had one 4 axes machine centre to perfect our own manufacturing process," explained Mark Pacy, a member of the SSI production team. Once we had proven the design and process we knew that demand would exceed the single machine so a duplicate was procured with the intention of automating the loading and unloading.

"No robotics skills existed in our company; we were complete novices, so we went out to several leading robot suppliers for help. Kawasaki Robotics offered the same work envelope arm as everyone else but had the benefit of a an extra 5Kg payload which we required. From the first contact we had support in the form of 3D model software for our own system and simulations to prove capability."

SSI wanted to undertake as much of the project as possible and use it as a learning curve in robotics; to support this process they were provided with a list of approved Kawasaki support engineers to assist as required. Alan Thompson, SSI's Machine Shop Foreman, explains, "We thought the machine interface and robot integration was a 'black art' but the engineer quickly completed all requirements. The whole process was more straight-forward than we thought it would be with continual support available from Kawasaki."

Space was at a particular premium at SSI and initial layouts positioned the machines opposite each other; Kawasaki suggested that a side by side machine positioning with the robot gaining access through the side access panels would allow faster setup times for tooling. This allowed an optimum 1.2 metre space for the robot to work in to include component racks and gauging.

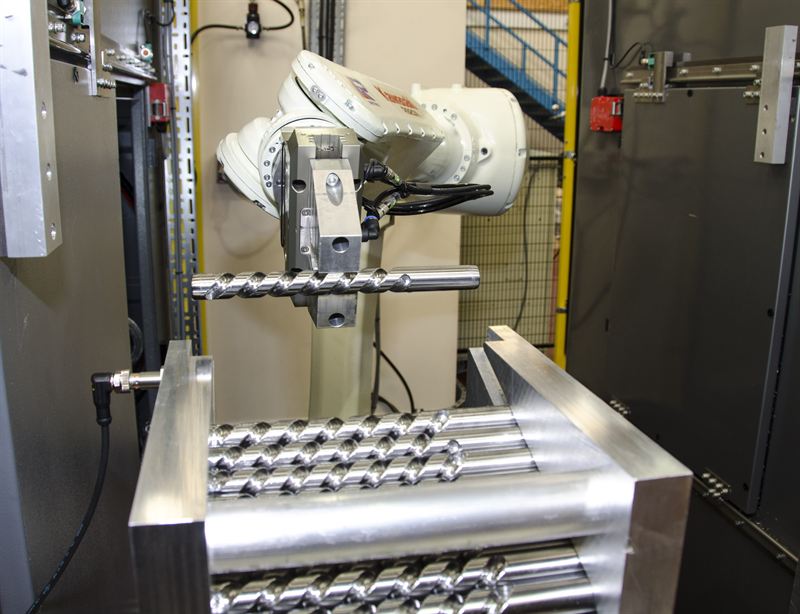

The cell is able to handle six variants of rotor which are loaded into magazines to allow for totally unmanned production at night. A single gripper design allows handling of all variants from 15 mm to 38 mm diameter.

"Our approach to everything was to keep it simple," continued Alan, "the gripper saves us changeover time and the magazines and programme selection are all we need to address during set-up. Utilising the robot to the full we use it to slide open and shut the side access door of each machine to avoid using actuators and should a jam occur in the gravity-fed magazine the robot can operate a slide hammer to vibrate the two magazine locations. Gauging is also managed by the robot on every component prior to loading."

Mark Pacy believes they have proved it is well within their capability to implement further robot installations and get it right, "Payback is looking to be particularly good on the robot and although it's too early to be precise we expect it to be under a year; we are already looking at the next operation downstream from the first cell.

"In summary the robot has proved to be a 'no brainer' solution for SSI; it's helped us to increase production and, as a result, to take on more people to keep the robot fed. And, as for our business, it has ensured we are the most competitive supplier in the World."

Image 01

Image 02

Image 03

Issue reference: Ka-031-A

Issue date: March 2015

Video: https://youtu.be/p2zam_77i8c

Photography and graphics: http://news.cision.com/kawasaki-robotics-uk-limited

Contact: davidw@jonoliver.com for high resolution image file.

Issued by:

davidw@jonoliver.com, Jon Oliver Communication Ltd. +44-(0)1902-757115

Further information:

Ian Hensman, UK Sales and Marketing Manager, Kawasaki Robotics UK Ltd

Unit 4, Easter Court, Europa Boulevard, Warrington WA5 7ZB

Tel +44 (0)1925 713000 begin_of_the_skype_highlighting email: ianhensman@kawasakirobotuk.com

Visit our web site: www.kawasakirobot.co.uk

Notes to editors:

Kawasaki Robotics (UK) Ltd is the UK robotics division of Kawasaki Heavy Industries Japan.

Based in Warrington, Kawasaki Robotics (UK) Ltd occupies a 15,000 Sq. Ft. Building. Its location provides easy access to the main motorway network and is at the centre of its customer base.

The facility centralises all the sales and customer support operations, with areas for customer demonstrations, training, robot test and integration and a large area for stock machines. Over 1,800 machines are now operating in a wide range of industries and applications throughout the UK.

Operating through a network of system partners, automation integrators and also supplying direct to end users, Kawasaki Robotics (UK) Ltd offers experience in the widest range of industry sectors.

Kawasaki Heavy Industries introduced its first industrial robot into the Japanese domestic market in 1969 and since then has developed into a world leader in the manufacture of industrial robots. Renowned world-wide for quality and technology in all its engineering systems and products, this philosophy is continued throughout the Kawasaki Robotics divisions.

Tags: