Leading Edge Materials Receives Engineering Study for Battery Graphite Demonstration Plant at Woxna, Sweden

Vancouver, BC, May 15, 2019 /CNW/ – Leading Edge Materials Corp. (“Leading Edge Materials” or the “Company”) (TSXV: LEM) (OTCQB: LEMIF) (Nasdaq First North: LEMSE) is pleased to announce receipt of an engineering study (the “Study”) for the installation and operation of a battery graphite demonstration plant at the Woxna mine site in Sweden.

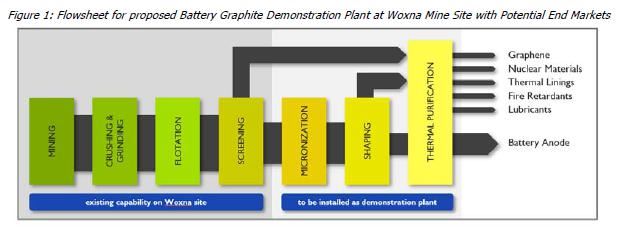

The Study was undertaken by a leading global engineering firm, using data from the extensive purification and spheronisation test work completed by the Company over past years (see press release dated 18th Jan 2019). The Study provides design, installation and cost estimate criteria for a spheronisation and thermal purification process that can deliver approximately 100kg per day of high purity natural graphite anode suitable for lithium ion batteries (see flowsheet Figure 1).

When installed, it is expected that the demonstration plant will deliver a substantial volume of natural graphite anode, enabling Woxna graphite to progress towards battery customer qualification. The thermal purification process is designed with a high degree of flexibility. Recent test work by Leading Edge Materials has produced ultra-high purity graphite up to 99.998% carbon and the process flexibility will allow purity to be tailored to customers performance and price requirements. Spheronisation test work produced D50 size ranges from 15-25 micron with D10 ranges of 7-12 micron and D90 from 28-35 micron. These ranges meet specifications provided by potential customers and are consistent with anode materials used by all current lithium ion battery manufacturers.

Technical information has been verified by Mr. Mark Saxon, Interim President and CEO of Leading Edge Materials and a Fellow of the Australasian Institute of Mining Metallurgy, being a qualified person under National Instrument 43-101 including the sampling, analytical, and test data underlying the information or opinions.

The demonstration plant is designed to deliver essential operating data, including energy requirements, cost, environmental and health and safety considerations that can be incorporated into mine scale design. The demonstration plant costing incorporates equipment manufacturer quotations, and is designed to be installed on the Leading Edge Materials Woxna mine site, where space, adequate power, skilled personnel and waste management facilities are already in place.

Furthermore, Leading Edge Materials has received written confirmation from the Gävleborg Länsstyrelsen (“County Administration Board”) that based on the engineered design, the demonstration will conform with current site permits.

Mark Saxon, Interim President and CEO, stated “After the considerable time dedicated to graphite anode process development and optimization, we are very pleased to have achieved this milestone for the Woxna graphite mine. As there is no natural graphite anode produced in Europe, we believe that installation of the demonstration plant will make a very significant contribution to the security of the emerging European lithium ion battery supply chain.”

Today, 100% of natural graphite anode is manufactured in China using chemical leaching which emits waste streams for treatment or disposal. In contrast, the thermal purification process designed for the Woxna demonstration plant requires no chemicals, instead using elevated temperature to remove impurities. The purification furnace at Woxna will be operated using cost competitive Swedish electrical power which is expected to result in a low carbon footprint.

Mr. Mark Saxon, Interim President and CEO of Leading Edge Materials and a Fellow of the Australasian Institute of Mining Metallurgy, being a qualified person under National Instrument 43-101, has supervised the preparation and approved the contents of this release.

On behalf of the Board of Directors, Leading Edge Materials Corp.

Mr. Mark Saxon, Interim CEO

Additional Information

The information was submitted for publication through the agency of the contact person set out above, at 15th May 2019 at 5:00 am Vancouver time.

Leading Edge Materials is listed on the TSXV under the symbol “LEM” and Nasdaq First North Stockholm under the symbol "LEMSE". Mangold Fondkommission AB is the Company’s Certified Adviser (“CA”) on Nasdaq First North and may be contacted at +46 (0) 8 5030 1550.

Reader Advisory

This news release may contain statements which constitute “forward-looking information”, including statements regarding the plans, intentions, beliefs and current expectations of the Company, its directors, or its officers with respect to the future business activities of the Company. The words “may”, “would”, “could”, “will”, “intend”, “plan”, “anticipate”, “believe”, “estimate”, “expect” and similar expressions, as they relate to the Company, or its management, are intended to identify such forward-looking statements. Investors are cautioned that any such forward-looking statements are not guarantees of future business activities and involve risks and uncertainties, and that the Company’s future business activities may differ materially from those in the forward-looking statements as a result of various factors, including, but not limited to, fluctuations in market prices, successes of the operations of the Company, continued availability of capital and financing and general economic, market or business conditions. There can be no assurances that such information will prove accurate and, therefore, readers are advised to rely on their own evaluation of such uncertainties. The Company does not assume any obligation to update any forward-looking information except as required under the applicable securities laws.

Woxna has never defined a mineral reserve and the previous preliminary economic assessment on Woxna dated October 29, 2013, has been superseded by the Company’s current technical report dated May 11, 2015. As the Woxna facility is not in production but remains on a production ready status, any future decision to recommence mining at Woxna will not be based on a preliminary economic assessment demonstrating the potential viability of mineral resources or feasibility study of mineral reserves demonstrating economic and technical viability. Under these circumstances, there is increased risk of technical and economic failure for the Woxna project, and the Company discloses additional risk factors relating thereto. The Company advises that it has not based its production decision on a feasibility study of mineral reserves, demonstrating economic and technical viability, and, as a result, there may be an increased uncertainty of achieving any particular level of recovery of minerals or the cost of such recovery, including increased risks associated with developing a commercially mineable deposit. Historically, such projects have a much higher risk of economic and technical failure. There is no guarantee that production will begin as anticipated or at all or that anticipated production costs will be achieved. Failure to commence production would have a material adverse impact on the Company’s ability to generate revenue and cash flow to fund operations. Failure to achieve any anticipated production costs would have a material adverse impact on the Company’s cash flow and future profitability. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accept responsibility for the adequacy or accuracy of this news release.

For further information, please contact the Company at:

1.604.685.9316

info@leadingedgematerials.com

www.leadingedgematerials.com

About Leading Edge Materials

Leading Edge Materials is a Canadian public company focused on production of high value critical raw materials for the European market, with an operating base in the Nordic region, a region well recognized for its promotion and investment in innovation. LEM’s flagship asset is the Woxna Graphite production facility located in central Sweden targeting the supply of specialty materials for lithium ion battery production.