It’s Showtime as Ravenwood Packaging puts its Complete Linerless System into action at LabelExpo in Chicago

International Linerless ‘coming to the rescue’ with label formats for everything …

and it’s GO for ready meal labelling

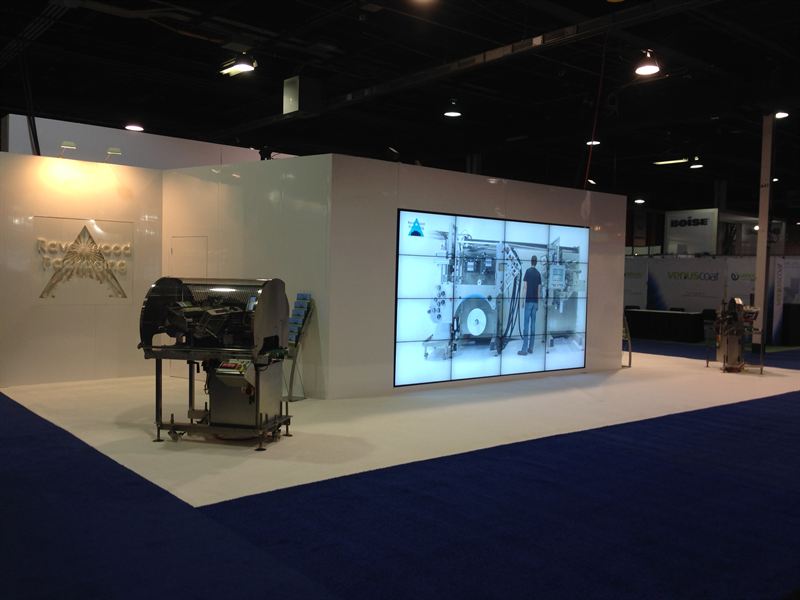

Linerless labelling specialist Ravenwood Packaging will be showcasing its ‘complete package’of converting and labelling technology at LabelExpo Americas (13-15 September) in Chicago on its new and futuristic stand – 5213.

The ‘less-waste packaging’ exhibition display will highlight coating and labelling in action, along with the development of the ultimate space age materials and adhesives to produce seamless linerless lines. The dynamic comic-hero-style ‘International Linerless to the Rescue’ story of how Ravenwood Packaging developed the linerless label alongside world leading materials suppliers will be told via the big screen, central to their stand. Ravenwood will also be part of the exhibitions Linerless Trail – www.linerless-trail.com

The flexible, adhesive-backed labels featured on the company’s website www.ravenwoodpackaging.com are now regularly used as the eco-friendly replacement for traditional labels that carry waste-creating backing paper. The increase in use of linerless labelling systems comes from the numerous sustainability initiatives around the world; and from pressure from consumers and environmental lobby groups. With 20 years of linerless experience and a range of labelling solutions to help increase production efficiency, the company is showcasing labelling for every kind of packaging sector from fish and meat to produce to dairy and ready meals.

The flexible, adhesive-backed labels featured on the company’s website www.ravenwoodpackaging.com are now regularly used as the eco-friendly replacement for traditional labels that carry waste-creating backing paper. The increase in use of linerless labelling systems comes from the numerous sustainability initiatives around the world; and from pressure from consumers and environmental lobby groups. With 20 years of linerless experience and a range of labelling solutions to help increase production efficiency, the company is showcasing labelling for every kind of packaging sector from fish and meat to produce to dairy and ready meals.

The company – based at a top secret facility in Bury St Edmunds, Suffolk - will be demonstrating its unique and original coating and application machines to the largest label and package printing audience across the Americas.

The Nobac 500R is set to reinvent the cardboard readymeal sleeve, the next stage on from the slideable sleeve for the ever expanding Ready Meal market. This label has a 100mm-225mm format with speed dependent on feed length but 65ppm is its aim. The machine is slightly longer than the standard Nobac 500 Sleever but is still very compact. This brings ready meals into the linerless arena for the very first time, proving that this technology can be applied to virtually any packaging challenge.

An Audio-Visual ‘expo-wall’ will roll out real-time big-screen footage of Ravenwood Packaging’s Comac 500 coating machines in action, running pre-printed webs. The Comac 500, running at speeds of up to 95m/min, will be taking printed master reels and making them ready for use on the company’s Nobac applicators, two of which will be featured at the show.

The Nobac 500 applies labels in five formats, varying from C-wrap and full wrap, to packs for chilled foods and convenience meals and handles up to 180 packs/minute.

Ravenwood supplies a range of specialist labels and packaging machines worldwide including those being used by an extensive number of manufacturers in Europe and the US, Latin America and Australia.

Speaking about Ravenwood’s premium position in the linerless market, MD Paul Beamish said:

‘The label and package printing sector is now seeing that the easiest trail to sustainability is linerless. This has moved from niche packaging to mainstream in a very short time. And it’s here to stay.

We are now moving into the ready meals market, one that is showing unstoppable growth in every country year on year.’

‘The UK is still possibly the most advanced country in Europe to produce chilled food packaging and we are proud to be at the forefront of this pioneering trend. Linerless labels bring less waste, less downtime and reduced transport costs. These changes make a substantial difference to a manufacturer’s profitability and sustainability rating and that’s why they are important. Ready meals are the way ahead as people find that they are time-poor above all things.’

‘Linerless labelling is perfect for food packaging and now including fresh produce and bakery products - but we are moving into areas other than food packaging, like healthcare, household, motor care and toiletries. We engineer ‘greener’ applicators and coaters which are taking ground from conventional labelling systems. The applicators are mega-flexible they can pack paper, card and film, so different packs can be produced during a day simply by changing the material used.’

Ravenwood Packaging has previously launched skin pack and slideable labels to answer the call for more linerless labelling products to fulfil more varied functions. ‘Slideable’ labels -which are made from thicker materials; up to 300gsm. These are linerless labels that can be applied automatically by Nobac 500 applicators. Unlike conventional linerless labels they slide on the pack allowing the customers to view the product inside.

The ‘slideable’ labels which can be produced with maximum dimensions of 500mm x 200mm are aimed at readymeal producers. The ‘sleeves’-with-a-difference are referred to as such because they come on a roll. They offer the advantages of lightweighting and automation.

‘Skin pack’ labelling is proving another popular linerless concept which can also be produced by Nobac machines. The main benefit of skin pack technology is that various products can be packed in fewer types/styles of trays as the product can be applied to fit to a standard tray which can simply incorporate large and smaller items. A major benefit of Ravenwood Packaging’s new ‘skin pack’ line is that they have formulated the optimum material for ‘super-protruding’ packs to include exceptionally bulky items such as roasting joints. Skinpack labelling also greatly extends shelf life.

Most of Ravenwood Packaging’s approved suppliers will attend the show and be part of the Linerless Trail including Ashland Coatings, Innovia, Evonik and Henkel which will allow visitors to discover how the complete linerless concept is put together.

To find out more visit www.ravenwood.co.uk.

Meet the Ravenwood Team for LabelExpo Americas: From left: David Mathison, Kristen Lucks, Jeremy Woodcock, Paul Beamish, Michael Peat and Dan Coe.

Ends

For further details contact Alison Baker at Madhouse PR on 01284 830321

or email madhousepr@aol.com or Paul Beamish at Ravenwood UK on 07989 561718 or 01284 or +44 (0)1284 749144 paul@ravenwood.co.uk or Michael Peart at Ravenwood USA on +1678 488 5434 mpeart@windstream.net

Tags: