Advanced Fabric Exhaust Insulation from Federal-Mogul Powertrain Enables Greater Design Flexibility, Higher Efficiency and Lower Emissions

Innovative knitted lightweight sleeving provides effective thermal containment, eliminates custom-tooling costs

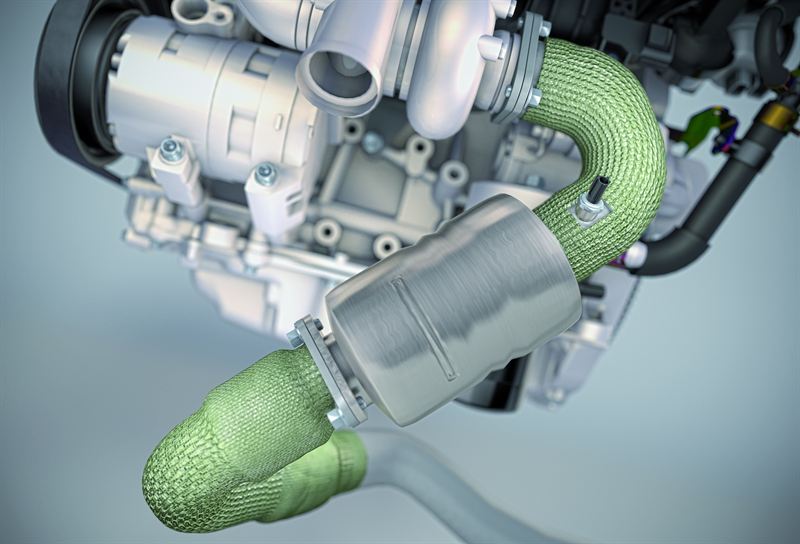

Crépy-en-Valois, France, 6 October 2016 … Federal-Mogul Powertrain, a division of Federal-Mogul Holdings Corporation (NASDAQ: FDML), has enhanced its innovative line of ThermFlex®exhaust insulating sleeves. The textile heat shield´s optimised design can now be tailored to fit almost any combination of exhaust pipe and tube geometries, helping to increase the efficiency of a vehicle exhaust system while protecting nearby sensitive components. Additionally, Federal-Mogul Powertrain’s unique flexible manufacturing process produces an exhaust sleeve that is application-specific without the need for custom tooling.

A knitted sleeve typically produced from inorganic fibres such as fibreglass, basalt and silica, ThermFlex traps heat within the exhaust system, benefitting both systems protection and emissions control. Federal-Mogul Powertrain has developed a family of different fabrics, with a specification of withstanding temperatures up to 1100°C. In the future, even temperatures up to 1800°C could be contained, depending on the materials used. The innovative product design allows the sleeve diameter to expand to up to twice its original size and can accommodate the flanges and bends common on exhaust system components, while the construction can be specified to include vents to strategically direct heat away from sensitive components. Customised built-in bracket spaces to ease installation while maintaining the integrity of the sleeving structure are also an option.

“ThermFlex insulating sleeves are a highly engineered solution, developed to give vehicle manufacturers the level of control that they need to meet stringent and evolving emissions regulations,” explained Janice Maiden, Senior Vice President, Federal-Mogul Powertrain Systems Protection. “This fully integrated product addresses environmental, thermal and durability requirements within one customised design that is also lighter than traditional solutions.” Depending on the layout and requirements, ThermFlex sleeves can reduce mass by 40 -60 percent compared to conventional rigid heat shields and installation is rapid, typically less than five seconds for a length up to 500 mm.

The textile heat shields complement Federal-Mogul Powertrain´s comprehensive systems protection portfolio. “We believe our ThermFlex sleeves are the only exhaust insulators in the marketplace to offer customised design options that accommodate packaging constraints,” said Maiden. “ThermFlex demonstrates our strategy for leading technology and innovation and is an excellent example of an enabling technology we provide to our customers to help them meet their objectives.”

Federal-Mogul uses proprietary computerised knitting technology to enable rapid prototyping of ThermFlex sleeves, cutting the lead time to production and eliminating tooling costs. During the knitting process, one continuous yarn is used with a specific needle stitch to create the unique knit structures. Several continuous yarns can be used to add further properties. Prototypes are modelled on the customer part and adjusted to ensure proper alignment. The entire prototype manufacturing phase takes just one to two weeks.

ThermFlex products are sold under the Bentley-Harris® and Federal-Mogul brand names.

About Federal-Mogul

Federal-Mogul Holdings Corporation (NASDAQ: FDML) is a leading global supplier of products and services to the world’s manufacturers and servicers of vehicles and equipment in the automotive, light, medium and heavy-duty commercial, marine, rail, aerospace, power generation and industrial markets. The company’s products and services enable improved fuel economy, reduced emissions and enhanced vehicle safety.

Federal-Mogul operates two independent business divisions, each with a chief executive officer reporting to Federal-Mogul's Board of Directors.

Federal-Mogul Powertrain designs and manufactures original equipment powertrain components and systems protection products for automotive, heavy-duty, industrial and transport applications.

Federal-Mogul Motorparts sells and distributes a broad portfolio of products through more than 20 of the world’s most recognized brands in the global vehicle aftermarket, while also serving original equipment vehicle manufacturers with products including braking, wipers and a range of chassis components. The company’s aftermarket brands include ANCO® wiper blades; BERU®* ignition systems; Champion® lighting, spark plugs, wipers and filters; Interfil® filters; AE®, Fel-Pro®, FP Diesel®, Goetze®, Glyco®, Nüral®, Payen® and Sealed Power® engine products; MOOG® chassis components; and Ferodo®, Jurid® and Wagner® brake products and lighting.

Federal-Mogul was founded in Detroit in 1899 and maintains its worldwide headquarters in Southfield, Michigan. The Company has more than 53,000 employees globally. For more information, please visit www.federalmogul.com.

*BERU is a registered trademark of BorgWarner Ludwigsburg GmbH

| CONTACT Paul Chadderton Market Engineering +44 (0)1295 277050 paul.chadderton@m-eng.com |

Ursula Hellstern Federal-Mogul Corporate Communications EMEA +49 (611) 201 9190 ursula.hellstern@federalmogul.com |

ASSETS

Images can be downloaded from our newsroom without registration

Alternatively, please contact sophie.kerlin@m-eng.com