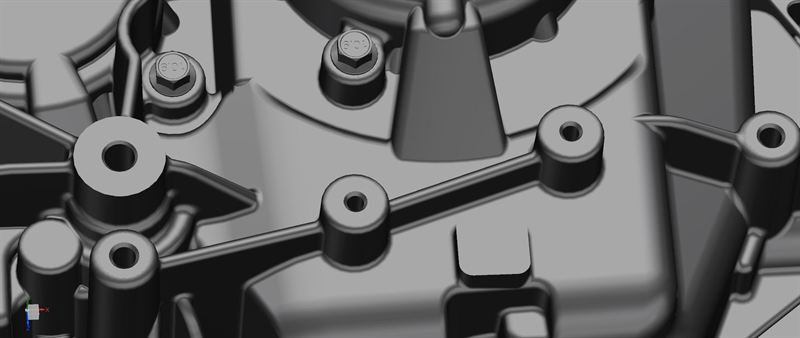

Lighter, More Efficient Transmissions Using Structural Plastics

Strategic partnership between transmission specialist and global chemical company creates new possibilities

Leamington Spa, UK, 26th May 2016 – A new development partnership will improve the efficiency and reduce the weight of automotive transmissions through the increased use of structural plastics. Automotive engineering consultancy, Drive System Design (DSD) and international chemical and advanced materials company, Solvay SA, aim to make the large scale use of plastic composites in transmissions a viable solution for future vehicles. DSD is contributing the transmission know-how while Solvay the materials expertise.

“The partnership began when we worked together on a plastic transmission housing to improve the NVH of an electric vehicle (EV),” explains DSD’s president, North America, Shaun Mepham. “The approach was so effective that it raised the possibility of improving the efficiency of the meshing gears by using tooth geometry that would normally be considered unacceptable because of noise.”

There is an immediate weight saving from substituting plastic materials for conventional metal castings but, equally important is the potential for improved efficiency due to the greater inherent damping provided by polymeric materials. This permits the use of gears that are much more efficient but would have unacceptable noise characteristics in a conventional casing. Examples of this approach include the use of reduced helix angles or spur gears and high efficiency tooth profiles with shorter height for reduced sliding and increased rolling.

Potential exists for shafts, casings and hydraulic cylinders to be made from plastic, suitably reinforced where appropriate. Full implementation could produce savings of up to 45% in terms of the casing weight for a typical passenger car transmission although with an NVH ‘skin’ included this reduces to 25%, but allows a reduction in transmission losses of up to 0.5% per gear mesh.

There remain a number of challenges to be overcome before this happens, according to Mepham. “New and unfamiliar materials bring pitfalls for the unwary because of the subtleties of the mechanical properties, which can change by up to 50% over the operating temperature range due to non-linear behaviour,” he says. “It’s always good practice to work with a materials supplier from the earliest stage of design but, when the material properties are as different as polymers and metals it is absolutely essential.”

DSD and Solvay are in discussions with vehicle manufacturers to determine the areas within transmission and driveline systems that offer the best potential for material substitution in the future. According to Solvay’s global automotive marketing manager, Mark Wright, it is important to approach potential customers with a range of alternative ideas. “Each customer has individual priorities, whether for weight reduction, NVH improvement or increased efficiency,” he says. “We have to reflect that by presenting the most appropriate options for their particular case.”

Currently, the technology is in the development phase to optimise the most suitable materials and processes in a ‘near production ready’ state. DSD and Solvay anticipate a five to ten year timescale before the first applications come to market. Once proven in niche applications such as premium EVs, and processing costs have been reduced by expanding the volumes, it could become a mainstream technology for passenger car transmissions.

About DSD

Drive System Design (DSD) is an award winning engineering consultancy specialising in the engineering, development and control of transmission and future driveline systems.

The company’s staff have experience working with vehicle manufacturers and Tier 1s around the world, designing new technologies and solving problems to make their products more competitive. They have the engineering, test, analysis and project management skills necessary to deliver projects to demanding timescales. Working closely with its customers through technical centres in Europe and North America, DSD is recognised as a world leading expert in driveline refinement, efficiency improvement and hybrid and electric vehicle transmissions. DSD is ISO 9001 and ISO 14001 certified.

Assets:

Assets can be downloaded from our newsroom without registration.

Alternatively, please contact megan.davies@m-eng.com

To download this release as a PDF please click here

Tags: