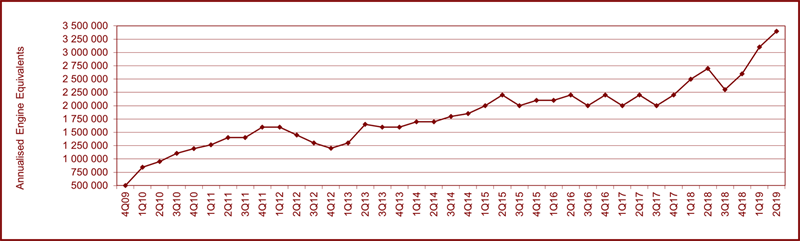

Second consecutive quarter with record series production

- Record annualised series production of 3.4 million Engine Equivalents in second quarter

- Record annualised monthly production of 3.5 million Engine Equivalents in May

- Installation revenue in second quarter surpasses previous full-year average

[Stockholm, 11 July 2019] – Annualised series production reached 3.4 million Engine Equivalents in the second quarter of 2019, surpassing the previous record of 3.1 million Engine Equivalents set in the first quarter. Following two consecutive quarters of record series production, the annualised series production for the first half of 2019 is 30% above the 2018 full-year production volume. The positive trend in the series production peaked during the month of May, reaching the new annualised record level of 3.5 million Engine Equivalents. The full-year outlook remains positive, with strong demand for SinterCast-CGI diesel engines used in Ford and Ram pick-up applications, and continued strong demand for commercial vehicle production.

Benefitting from additional revenue derived from Tracking Technologies, installation revenue after the second quarter reached SEK 7.1 million, surpassing the historical full-year average of approximately SEK 6.5 million. The strong installation result includes the first full installation of the Cast Tracker technology at the Tupy foundry in Mexico and the first Ladle Tracker installation for ductile iron production at the Poitras foundry in Canada. Additional revenue was derived from Mini-System 3000 installations at the China Shipbuilding Industries Corporation foundry for industrial power components in China and at the Kimura rapid prototyping foundry in the United States; and from capacity and functionality upgrades of existing System 3000 installations.

“Following year-on-year growth of 24% from the first-half of 2017 to 2018, we have now achieved 25% year-on-year growth in the first half of 2019. The record production of 3.4 million Engine Equivalents in the second quarter validates the gains made over the last two years, and reinforces the current level as our new normal” said Dr. Steve Dawson, President & CEO of SinterCast. “The second quarter was particularly busy for SinterCast, with four installations in the field and the equipment builds for the GIFA world foundry trade fair in June. With a strong installation start in the first half of the year, and with ongoing discussions and new leads established at GIFA, we look forward to adding to the installation revenue in the second half of the year.”

Series production continued to grow in the second quarter, reaching an annualised record of 3.4 million Engine Equivalents for the quarter, providing 30% growth compared to full-year 2018. Series production reached the new all-time high of 3.5 million Engine Equivalents in May.

For more information:

Dr. Steve Dawson

President & CEO

SinterCast AB (publ)

Tel: +44 771 002 6342

e-mail: steve.dawson@sintercast.com

SinterCast is the world’s leading supplier of process control technology for the reliable high volume production of Compacted Graphite Iron (CGI). With at least 75% higher tensile strength, 45% higher stiffness and approximately double the fatigue strength of conventional grey cast iron and aluminium, CGI allows engine designers to improve performance, fuel economy and durability while reducing engine size, weight, noise and emissions. The SinterCast technology is used for the production of petrol and diesel engine cylinder blocks and exhaust components for passenger vehicles, medium-duty and heavy-duty cylinder blocks and heads for commercial vehicles, and industrial power engine components for agriculture, marine, rail, off-road and stationary engine applications. SinterCast supports the series production of components ranging from 2.7 kg to 9 tonnes, all using the same proven process control technology. As a specialist supplier of precision measurement and process control solutions to the metals industry, SinterCast also supplies a suite of tracking technologies, including the SinterCast Ladle Tracker®, Cast Tracker™ and Operator Tracker™, to improve process control, productivity and traceability in a variety of applications. With 54 installations in 14 countries, SinterCast is a publicly traded company, quoted on the Small Cap segment of the Nasdaq Stockholm stock exchange (SINT). For more information: www.sintercast.com

END

Tags: