SinterCast Results January-March 2019

Record series production; positive outlook for 2019

First Quarter 2019

- Revenue for Period: SEK 22.9 million (SEK 16.6 million)

- Operating Result: SEK 8.9 million (SEK 4.9 million)

- Earnings per Share: SEK 1.2 per share (SEK 0.6 per share)

- Cashflow from Operations: SEK 6.9 million (SEK 7.7 million); due to increased operating receivables

- Record series production of 3.4 million Engine Equivalents in March

- Record series production of 3.1 million Engine Equivalents in first quarter; 24% year-on-year increase

- High-volume installation commitment for commercial vehicle production at new Scania foundry

- Mini-System 3000 installation at Jönköping Technical University in Sweden for CGI development

- Installed Base: 25 (24) fully automated systems, 23 (21) mini-systems and four (one) tracking systems in 14 (13) countries

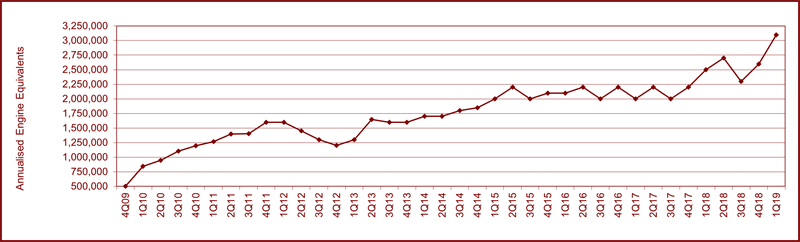

Series Production*

Building on the start of production of the Cummins 6.7 litre in-line diesel engine used in Ram Super Duty pick up applications, series production increased to the record level of 3.1 million Engine Equivalents in the first quarter of 2019, providing 24% year-on-year growth.

* Annualised average production of Engine Equivalents during the quarter (1 Engine Equivalent = 50 kg)

CEO Comments

Second consecutive year with strong start for series production

Following 25% year-on-year growth in the first quarter of 2018, series production took another significant step forward in the first quarter of 2019, posting 24% year-on-year growth and finishing at the new quarterly record level of 3.1 million Engine Equivalents. The increase in the first-quarter production was primarily due to the ramp-up of the Cummins 6.7 litre in-line diesel engine that started production at the Tupy Mexico foundry during the fourth quarter of 2018. From the foundation of 2.6 million Engine Equivalents in the fourth quarter of 2018, series production reached the 3.0 million Engine Equivalent milestone in February and increased further to the new monthly record level of 3.4 million Engine Equivalents in March. The first quarter volume also benefitted from increased production of V-type diesel engines for passenger vehicles and from heavy-duty diesel engine cylinder blocks and heads for commercial vehicles, particularly in March.

The increased series production, plus a 13% increase in year-on-year Sampling Cup shipments, resulted in a 38% increase in first quarter revenue to SEK 22.9 million and an 82% increase in the first quarter operating result, to SEK 8.9 million. The full-year outlook remains positive, with stable contribution from the established series production base and opportunities for new installations for both the core CGI technology and for the new Tracking Technologies.

Positive outlook for installation revenue

The 2019 installation campaign also benefitted from a strong start, with two new installations secured in January. The first was a Mini-System 3000 installation for industrial power production at the China Shipbuilding Industry Corporation (CSIC) foundry in Shaanxi, China. The CSIC installation and training are underway and the system is expected to be fully commissioned before the end of the second quarter. The second installation commitment was for a full System 4000 Plus to be installed at the new Scania foundry during 2020. With an initial order value of approximately SEK 5 million, and with the start of series production beginning in 2021 and potentially ramping to provide approximately SEK 20 million of incremental running revenue per year before 2025, the Scania order represents a significant step in our long term growth plans and provides the opportunity for SinterCast to continue to deliver double-digit growth. Together with two Tracking Technologies installations that were ordered in 2018 but will be commissioned in 2019, the CSIC and Scania installations provide the opportunity for above average installation revenue in 2019 and 2020.

The 2019 installation activity was augmented in early-April by the installation of a Mini-System 3000 at the Department of Materials and Manufacturing at the School of Engineering at Jönköping Technical University in Sweden. The installation is part of the SinterCast contribution to a long-term university-industry project involving multiple industrial partners for the development of Compacted Graphite Iron (CGI), funded in part by the Swedish government. As part of the in-kind contribution, SinterCast will provide the Mini-System 3000 hardware and consumables, together with technical support for the use of the system and technical input to the project. The objective of the project is to develop new technologies and applications for CGI that further strengthen the position of Swedish industry.

Several other installation discussions are ongoing for CGI process control systems, capacity upgrades, and Tracking Technologies installations in grey iron, CGI and ductile iron foundries. In addition to these current installation opportunities, SinterCast is also investigating the development of other unique technologies – within and beyond the scope of thermal analysis – to improve quality and production efficiency in the metals industry, and to broaden our product portfolio and our production base.

Information

| Interim Reports |

Publication Date |

|

| April-June 2019 | 22 August 2019 | |

| July-September 2019 | 13 November 2019 | |

| October-December 2019 and Full Year Results 2019 | 19 February 2020 | |

| January-March 2020 |

22 April 2020 |

This report has not been reviewed by the company's Auditors.

Stockholm 24 April 2019

For further information please contact:

Dr. Steve Dawson

President & CEO

SinterCast AB (publ)

Office: +46 150 794 40

Mobile: +44 771 002 6342

e-mail: steve.dawson@sintercast.com

website: www.sintercast.com

This press release contains information SinterCast AB (publ) is obliged to make public pursuant to the EU Market Abuse Regulation. This information was submitted for publication, through the agency of the President & CEO Dr. Steve Dawson, at 08:00 CET on 24 April 2019.

SinterCast is the world’s leading supplier of process control technology for the reliable high volume production of Compacted Graphite Iron (CGI). With at least 75% higher tensile strength, 45% higher stiffness and approximately double the fatigue strength of conventional grey cast iron and aluminium, CGI allows engine designers to improve performance, fuel economy and durability while reducing engine size, weight, noise and emissions. The SinterCast technology is used for the production of petrol and diesel engine cylinder blocks and exhaust components for passenger vehicles, medium-duty and heavy-duty cylinder blocks and heads for commercial vehicles, and industrial power engine components for agriculture, marine, rail, off-road and stationary engine applications. SinterCast supports the series production of components ranging from 2.7 kg to 9 tonnes, all using the same proven process control technology. As a specialist supplier of precision measurement and process control solutions to the metals industry, SinterCast also supplies a suite of tracking technologies, including the SinterCast Ladle Tracker®, Cast Tracker™ and Operator Tracker™, to improve process control, productivity and traceability in a variety of applications. With 52 installations in 14 countries, SinterCast is a publicly traded company, quoted on the Small Cap segment of the Nasdaq Stockholm stock exchange (SINT). For more information: www.sintercast.com

END

Tags: