SinterCast Results July-September 2017

Operating result decreases due to order timing for Sampling

Cups and installations; series production improves

Third Quarter 2017

- Revenue for Period: SEK 16.7 million (SEK 23.8 million)

- Operating Result: SEK 4.7 million (SEK 11.2 million)

- Earnings per Share: SEK 0.7 per share (SEK 1.6 per share)

- Cashflow from Operations: SEK 1.0 million (SEK 7.0 million)

- Automation and capacity upgrades commissioned at Teksid and Tupy in Mexico

- Start of production of large piston rings at Total Solutions & Power Company in Korea

- Installation and upgrade discussions intensify for both CGI and Tracking Technologies

2017 Year-to-Date

- Revenue for Period: SEK 47.8 million (SEK 58.2 million)

- Operating Result: SEK 12.3 million (SEK 21.6 million)

- Earnings per Share: SEK 1.9 per share (SEK 3.1 per share)

- Cashflow from Operations: SEK 8.4 million (SEK 14.4 million)

- Installed Base: 24 fully automated systems and 20 mini-systems in Europe, Asia and the Americas

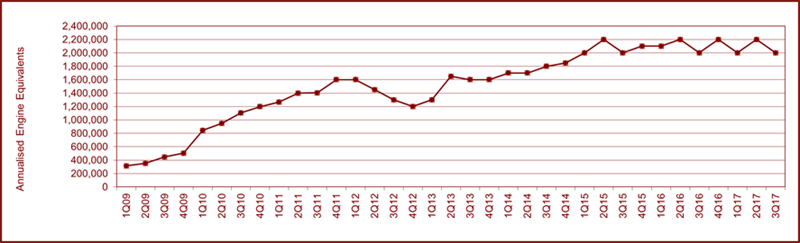

Series Production*

Annualised series production in the third quarter finished at 2.0 million Engine Equivalents, affected by

traditionally low volume in July. Key high-volume programmes and Sampling Cup shipments grew in August

and September, providing a positive outlook for the fourth quarter.

* Annualised average production of Engine Equivalents during the quarter (1 Engine Equivalent = 50 kg)

CEO Comments

Positive outlook as series production shows continued recovery

Following a difficult start to the year, with three high-volume programmes temporarily at reduced volume, series production improved in the third quarter. Two of the three programmes have recovered, although a traditionally quiet July limited the ability of 3Q 2017 to gain ground on the first three quarters of 2016. Several programmes posted strong results in August and September, providing the basis for the positive production outlook.

Despite year-to-date production being 1.6% behind 2016, the year-to-date revenue from series production is 12% below 2016. This is primarily due to the reduction in Sampling Cup shipments, from 133,800 in the first three quarters of 2016 to 102,200 in 2017. In consideration of the stable series production, it is evident that the difference in Sampling Cup shipments is due to order timing in 2016 followed by inventory adjustment in 2017, rather than any underlying reflection on the current or the future production outlook. The year-on-year comparison of the series production revenue in the third quarter was further exacerbated by the fact that 3Q16 was the highest-ever quarter for Sampling Cup shipments. Putting the Sampling Cup volume in perspective, only three quarters in history were higher than the third quarter of 2017. Thus far in 2017, Sampling Cup shipments increased 15% from the first quarter to the second quarter, and 23% from the second quarter to the third quarter, showing a rebuild of customer stock levels and reinforcing the positive outlook for the Sampling Cup shipments in the fourth quarter.

Total year-to-date revenue decreased by 18% due to comparatively higher installation revenue in the third quarter of 2016, resulting from the shipment of the System 3000 Plus to Teksid do Brazil. The resulting revenue of SEK 5.9 million in the third quarter of 2016 provides a difficult comparison basis for the current quarter, particularly in consideration that the average full-year installation revenue from 2010 through 2016 was SEK 7.6 million.

Capacity upgrades completed in Mexico; New series production underway in Korea

The upgrades of the existing System 3000 installations at the Tupy foundry in Saltillo, Mexico and the Teksid foundry in Monclova, Mexico have been successfully commissioned, providing automated base treatment capability and increased production capacity. The upgrades were ordered in advance of the start of production of a new high-volume CGI cylinder block at Tupy and the start of production of a new industrial power engine component at Teksid.

During the period, Total Solutions & Power Company (TSP), began series production of SinterCast-CGI piston rings in Korea. The start of production at TSP has been motivated by the increased market demand for CGI piston rings, as MAN Diesel & Turbo SE has introduced a new piston ring solution that uses three CGI rings instead of the conventional four-ring pack, where only the top piston ring was made of CGI. With diameters ranging from 300 to 700 mm, the CGI piston rings are used in large industrial power engines, primarily for the marine and stationary power markets.

New installation discussions are ongoing for CGI process control systems, and for the expansion of existing installations to increase capacity or to incorporate additional process control features. Beyond the core CGI activity, the installation intensity has been augmented by the introduction of the SinterCast Ladle Tracker®, Cast Tracker™ and Operator Tracker™ technologies. The Tracking Technologies have been well received in the industry, adding to the recognition of SinterCast as a creative and competent provider of unique precision measurement and process control technologies to the metals industry. Tracking discussions are ongoing for CGI applications, grey and ductile iron foundries, and for other metal processing applications. As production references become established, the suite of Tracking Technologies will begin to contribute to the total installation revenue. In addition to the new tracking opportunities, SinterCast is also investigating the development of other unique technologies – within and beyond the scope of thermal analysis – to improve quality and production efficiency in the metals industry.

Nomination Committee

The Nomination Committee, elected by the Annual General Meeting 2017, consists of Ulla-Britt Fräjdin-Hellqvist, Chairman, Andrea Fessler, Hans-Erik Andersson, Chairman of the Board of Directors and Aage Figenschou. Shareholders wishing to provide input or proposals should provide written submissions to the Nomination Committee (e-mail: nomination.committee@sintercast.com) at least seven weeks prior to the Annual General Meeting for the proposal to be included in the notice of the meeting.

Annual General Meeting

The Annual General Meeting 2018 of SinterCast AB (publ) will be held on Thursday 24 May 2018.

Shareholders wishing to have a matter considered at the Annual General Meeting should provide written submissions to agm.registration@sintercast.com or to the company: SinterCast AB (publ), Kungsgatan 2, 641 30 Katrineholm, Sweden, at least seven weeks prior to the Annual General Meeting for the proposal to be included in the notice of the meeting. Further details on how and when to register will be published in advance of the Annual General Meeting.

Information

The Interim Report October-December and Full Year Results 2017 will be published on 21 February 2018

The Interim Report January-March 2018 will be published on 25 April 2018

The Interim Report April-June 2018 will be published on 22 August 2018

The Interim Report July-September 2018 will be published on 21 November 2018

This report has been reviewed by the company’s Auditors.

Stockholm 22 November 2017

For further information please contact:

Dr. Steve Dawson

President & CEO

SinterCast AB (publ)

Office: +46 150 794 40

Mobile: +44 771 002 6342

e-mail: steve.dawson@sintercast.com

website: www.sintercast.com

This press release contains information SinterCast AB (publ) is obliged to make public pursuant to the EU Market Abuse Regulation. This information was submitted for publication, through the agency of the President & CEO Dr. Steve Dawson, at 08:00 CET on 22 November 2017.

SinterCast is the world’s leading supplier of process control technology for the reliable high volume production of Compacted Graphite Iron (CGI). With at least 75% higher tensile strength, 45% higher stiffness and approximately double the fatigue strength of conventional grey cast iron and aluminium, CGI allows engine designers to improve performance, fuel economy and durability while reducing engine size, weight, noise and emissions. The SinterCast technology, with 44 installations in 13 countries, is primarily used for the production of petrol and diesel engine cylinder blocks and exhaust components for passenger vehicles, medium-duty and heavy-duty cylinder blocks and heads for commercial vehicles, and industrial power engine components for marine, rail, off-road and stationary engine applications. SinterCast supports the series production of components ranging from 2 kg to 9 tonnes, all using the same proven process control technology. As a specialist supplier of precision measurement and process control solutions to the metals industry, SinterCast also supplies a suite of tracking technologies, including the SinterCast Ladle Tracker®, Cast Tracker™ and Operator Tracker™, to improve process control, productivity and traceability in a variety of applications. The SinterCast share is quoted on the Small Cap segment of the Nasdaq Stockholm stock exchange (SINT). For more information: www.sintercast.com

END

Tags: