HYDROCAM hydraulic bolt tensioners remove uncertainty from couplings

Bolted assembly failures due to incorrect tightening can become a thing of the past, thanks to HYDROCAM hydraulically operated bolt tensioners

Gothenburg, Sweden, 4 June 2020: HYDROCAM hydraulically operated bolt tensioners are designed to offer far greater accuracy compared with alternative fixing methods. HYDROCAM removes uncertainty over the performance and long-term reliability of couplings. It also saves time and reduces risks, with its superior control and safety. Damage to bolts and associated structures is avoided, installation is faster, operation of equipment is optimised, while maintenance needs are minimised.

Bolted assemblies are used throughout industry but can present significant challenges. For example, incorrect assembly accounts for around 45% of all fatigue failures, with common problems being insufficient preload, over- or under-tightening and misalignment.

“Conventional methods for tightening bolts use torque, applied by hand or torque tools,” explains Damian Lewis, General Manager at Pilgrim, part of the SKF Group. “These methods can damage threads and flange faces, leading to re-machining and added downtime. The bolts may also become loose over time and need re-tightening. An alternative is heat induction, but this requires specialist contractors and additional cost.”

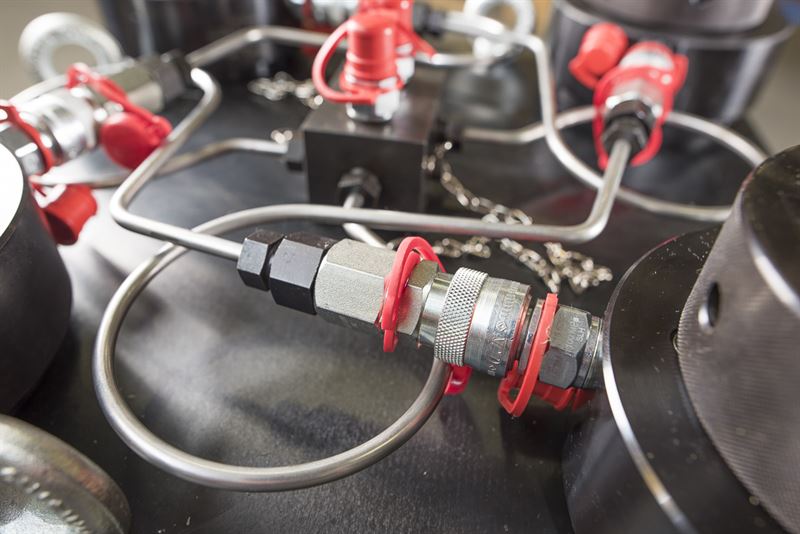

HYDROCAM overcomes these problems by axially stretching bolts and studs, using a pre-determined residual load to create a high integrity fixing, which can be mounted and dismounted quickly and safely without damage. HYDROCAM can be supplied as a single tool or incorporated into a multi-tensioner for homogenous tightening; in most applications it is intended to be reused with multiple fittings but can also be permanently incorporated into the nut assembly.

HYDROCAM is manufactured by Pilgrim, a fully owned SKF company, and supplied ready for use with the tensioner unit, power pack and all relevant fittings; the power pack can be hydraulically, electrically or hand operated.

Damian Lewis concludes, “HYDROCAM ensures consistent, safe and precise bolt assembly and fastening. It’s simple to use, eliminates the risk of errors and saves engineers throughout industry considerable time, effort and cost.”

Aktiebolaget SKF

(publ)

For further information, please contact:

Press Relations: Nia Kihlström, +46 31-337 2897; +46 706 67 28 97; nia.kihlstrom@skf.com

SKF’s mission is to be the undisputed leader in the bearing business. SKF offers solutions around the rotating shaft, including bearings, seals, lubrication, condition monitoring and maintenance services. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2019 were SEK 86 013 million and the number of employees was 43,360. www.skf.com

® SKF is a registered trademark of the SKF Group.

® HYDROCAM is a registered trademark of the SKF Group.