Developing battery technology for hybrid and electric powertrains

- Lithium-ion batteries have potential to reach 280 Wh/kg energy density

- Batteries twice as powerful as current ones due in next five years from Bosch

- Electric vehicle batteries have more than one lifetime

- Automated driving could change battery technology

Today’s lithium-ion batteries, for example, have to be designed to run for at least 150,000 kilometres and to last up to 15 years. Even then, after spending all this time in the car, the battery still has to possess 80 percent of its original storage capacity and performance. Within the next five years, Bosch intends to offer high-voltage batteries that are twice as powerful. At the same time, the company is exploring new battery technologies.

Development: the path to the next generation of lithium-ion batteries

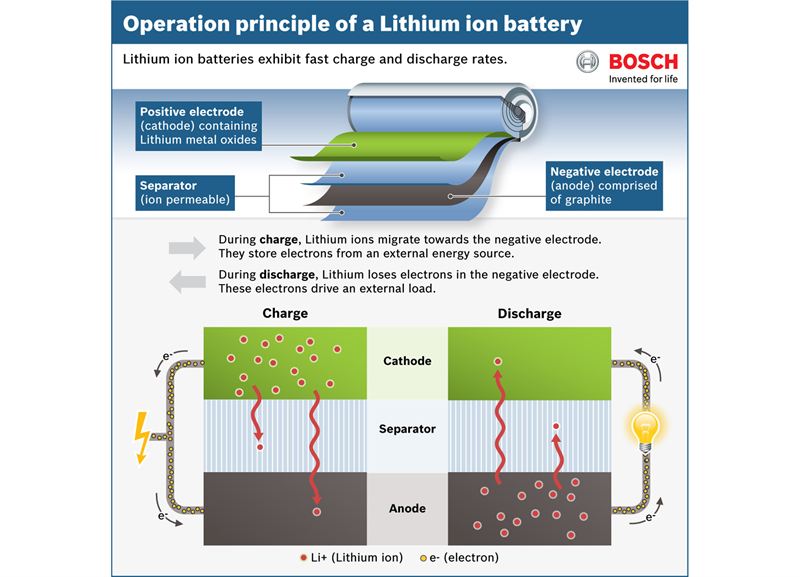

Lithium-ion technology: Today’s lithium-ion batteries have an energy density of approximately 115 Wh/kg, but have the potential to go as high as 280 Wh/kg. To research the next generation of lithium-ion batteries, Bosch has joined forces with GS Yuasa and Mitsubishi Corporation in a joint venture called Lithium Energy and Power. “The goal of this joint venture is to make lithium-ion batteries up to two times more powerful,” says Dr. Joachim Fetzer, member of the executive management of the Gasoline Systems division of Robert Bosch GmbH responsible for electromobility.

Beyond lithium-ion: Bosch’s corporate research department is working on future batteries, such as those made using lithium-sulfur technology, which promises greater energy density and capacity. Bosch estimates that the earliest the lithium-sulfur battery will be ready for series production is the middle of the next decade.

Progress: battery management results in 10 percent more range

Battery management: In terms of high-performance batteries, Bosch is focusing on driving forward the monitoring and management of the various cells as well as the overall system. Sophisticated battery management can further increase the range of a car by up to 10 percent – without altering the cell chemistry.

Infrastructure: automated vehicles have an effect on battery technology

Rapid charging points: If there are lots of places where you can quickly charge your electric vehicle, then this will have a major impact on battery technology. The faster an electric vehicle’s battery can recharge, the less important its range becomes.

Automated driving: Fully automated vehicles make charging much more straightforward, since they can search for charge spots without any assistance from the driver. How this works is demonstrated by V-Charge, a project spearheaded by Bosch, VW, and a number of European universities. The idea is that within a parking garage, for instance, the driver would be able to use a smartphone app to direct their electric vehicle to a charge spot. When the driver comes back, the car returns to the pick-up spot by itself.

Three lifetimes: for a high-voltage battery, the car is just the first step

Different stages in the life of a battery: A fleet vehicle, which drives a significant distance in a short space of time, requires a new battery with full performance and capacity. In contrast, a slightly used battery can work just as well in cars that are driven only occasionally for short routes. That would reduce the overall cost of an electric car. Even after twelve years – the average service life of a car – the battery still retains 80 percent of its original performance and capacity. This means its components can still be useful, for example as a power storage unit.

‘Second Life’ project with BMW and Vattenfall: In Hamburg, used batteries from electric vehicles are being joined together to form a large power storage system. It can provide energy within seconds and helps stabilise the grid. With this project, Bosch, the BMW Group, and Vattenfall are working together to drive electromobility and energy storage forward.

Contact: Sabrina Mayeen, 44 (0) 1895 838813

Mobility Solutions is the largest Bosch Group business sector. According to preliminary figures, its 2014 sales came to 33.3 billion euros, or 68 percent of total group sales. This makes the Bosch Group one of the leading automotive suppliers. Mobility Solutions largely operates in the following areas: injection technology for internal-combustion engines, alternative powertrain concepts, efficient and networked powertrain peripherals, systems for active and passive driving safety, assistance and comfort functions, technology for user-friendly infotainment as well as car-to-car and Car2X communication, and concepts, technology, and service for the automotive aftermarket. Bosch has been responsible for important automotive innovations, such as electronic engine management, the ESP anti-skid system, and common-rail diesel technology.

The Bosch Group is a leading global supplier of technology and services. According to preliminary figures, its roughly 290,000 associates generated sales of 48.9 billion euros in 2014. Its operations are divided into four business sectors: Mobility Solutions, Industrial Technology, Consumer Goods, and Energy and Building Technology. The Bosch Group comprises Robert Bosch GmbH and its more than 360 subsidiaries and regional companies in some 50 countries. If its sales and service partners are included, then Bosch is represented in roughly 150 countries. This worldwide development, manufacturing, and sales network is the foundation for further growth. In 2014, Bosch applied for some 4,600 patents worldwide. The Bosch Group’s strategic goal is to deliver innovations for connected life. Bosch improves quality of life worldwide with products and services that are innovative and spark enthusiasm. In short, Bosch creates technology that is “Invented for life.”

Additional information can be accessed at www.bosch.co.uk and www.bosch-press.com.

Follow us on Twitter/BoschUK and Facebook/BoschUK

Tags: