Aerospace engineering research on testing to produce safer, faster, more reliable aircraft

Office of Naval Research grant studies composites using variety of methods

A University of Texas at Arlington aerospace engineer is developing diagnostic and predictive tools that can aid aircraft manufacturers in analyzing composite structures used to make aircraft safer, faster and more reliable.

Andrew Makeev, an associate professor of Mechanical and Aerospace Engineering, is studying how to improve and integrate design and manufacturing processes to advance the performance of composite materials used in aircraft structures. The work is funded by a $559,427 grant from the Office of Naval Research.

“When a single yoke for a helicopter can cost upward of $100,000, it’s important to be able to predict its performance, in other words do most of the testing on a computer before taking it out into the field,” said Makeev, who joined UT Arlington in 2011 and previously served as the principal engineer for risk analysis at Delta Airlines. “We have to understand how the composite will behave under stress. That’s where three-dimensional nondestructive measurements and computer simulations come in. Composites have manufacturing irregularities in them that aren’t visible to the naked eye. We need to find those irregularities and understand their effects.”

Makeev’s work serves as an important bridge between innovation in university laboratories and the aircraft and rotorcraft industry, said Erian Armanios, chair of the Mechanical and Aerospace Department in the College of Engineering. It’s timely and provides critical support for the growing implementation of composites, he said.

“Businesses around the globe need this kind of partnership with university researchers to develop new ways of looking at manufacturing processes, determine composites’ properties and predict their performance,” Armanios said. “UT Arlington engineers are key players in supporting the aerospace industry’s focus on building cost-effective, reliable vehicles that meet challenging mission requirements. The progress achieved can be transferred to building greener cars, efficient wind turbines and bridges, to name a few. “

Composites are used in aircraft manufacturing because they allow for stronger and more durable construction at lower weight compared to metallic structures. Due to superior characteristics and the ability to tailor their properties, composite materials can increase the performance characteristics of aircraft as well as increase safety and reliability.

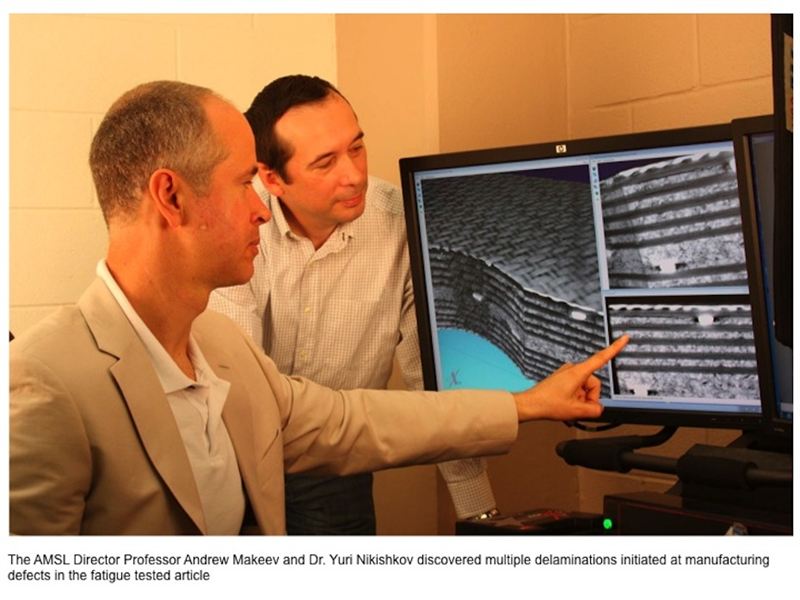

Makeev said his research has been successful because he integrates multiple methods to evaluate composite materials and structures. For example, computed tomography, an X-ray based three-dimensional imaging technology, is used to detect and measure defects in the composite. Three-dimensional modeling is used to measure the mechanical properties of those composites using a minimum number of tests. The measurements are transferred to a structural analysis model that captures failure modes, he said.

Makeev directs the Advanced Materials and Structures Lab at UT Arlington and represents UT Arlington in the Vertical Lift Consortium, a national organization comprised of U.S. rotorcraft industry and academic institutions involved in the vertical lift aircraft research with the common goal of providing long-term advancement of rotorcraft. He leads the Advanced Materials Technology Research at VLC and participates in a number of other VLC efforts including durability and damage tolerance, and condition-based maintenance technology. Makeev also represents UT Arlington in the Vertical Lift Research Center of Excellence, a multi-university organization funded by the U.S. Army to conduct fundamental research in rotorcraft areas.

In collaboration with Bell Helicopter Textron, Makeev and his research colleagues have unequivocally demonstrated that manufacturing irregularities, introduced due to the inherent variability of the way composites are manufactured, affect their structural performance.

Makeev said that industry needs tools to design better composite parts through integration of design and manufacturing processes at early design stages. Once the effects of the manufacturing process, including the irregularities, are captured, structural designs can be improved. Because the design and production phases for composite parts are so expensive, it is too late to redesign a composite part if problems are found during full-scale testing at the final design stage, he said.

Makeev’s work is representative of research excellence at The University of Texas at Arlington, a comprehensive research institution of more than 33,800 students and 2,200 faculty members in the heart of North Texas. Research activity has more than tripled over the past decade to $71.4 million last year with an emphasis on bioengineering, medical diagnostics, micro manufacturing, advanced robotics and defense and Homeland Security technologies, among other areas. Visit www.uta.edu to learn more.

Herb Booth, hbooth@uta.edu, 817-272-7075

The University of Texas at Arlington, www.uta.edu

Tags: