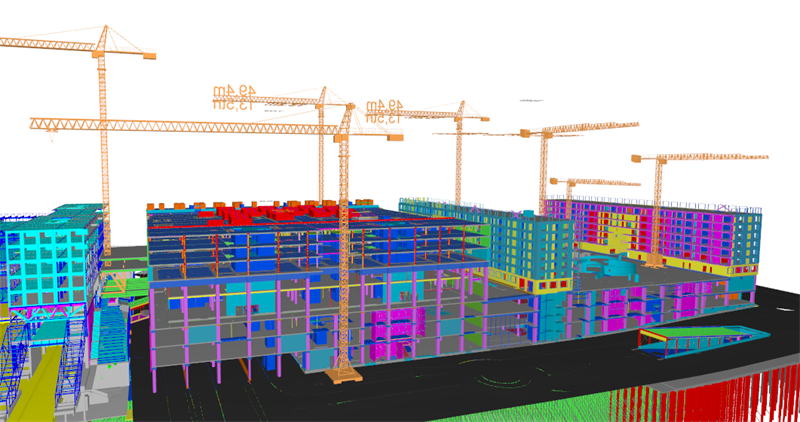

Cities are first built virtually

YIT CORPORATION News September 11, 2018 at 10:00 a.m.

Conventional paperwork at construction sites is being replaced with digital solutions. Virtual twins are already created of buildings, making their design, construction and maintenance more efficient. The data capabilities required for virtualisation and artificial intelligence solutions are not built in the blink of the eye, but when the groundwork is done properly, the digital performance leap will also extend to the rest of the built-up environment besides construction sites.

Even though news headlines tell of 3D-printed houses, the construction site is still visible towards the random passer-by as a conventional place where people toil, and machines make noise. However, a major change is brewing under the surface. The volume of data in the construction industry is about to explode and open the gates to an enormous performance leap.

The change has not taken place overnight. Marko Oinas, Vice President, Strategy & Development, Housing at YIT became familiar with the digitalisation of construction already more than 20 years ago when he was writing his thesis for YIT on Building Information Model-based (BIM) engineering.

“At the time, the market and the stakeholders were not ready yet, and digital tools had not evolved enough to obtain the full benefit of BIMS, either. Now, technology and expertise have taken a giant leap forward. BIMs are important to YIT from the beginning of project design,” Oinas says.

The construction industry has long experience in the use of 2D plan views and drawings. With 3D BIMs, the engineering work takes place three-dimensionally, which provides many benefits. They make it easier for the engineers, builders, maintainers and users to visualise and perceive the big picture and highlight the details essential to their own interest.

In addition, BIM contains a lot more of detailed data, as the name suggests. At YIT, data has been collected into a BIM library that contains proven certain structures and technical details. Such a databank makes it possible to design buildings far in advance and forecast the costs of different alternatives.

“The data is enriched until the completion of construction, and even after it. A digital twin is created for the building, and it can also be utilised in the maintenance and renovations of the property in future,” Oinas says.

Digital twins also contribute to reducing the amount of work carried out at the construction site. When there is an accurate digital twin of bathroom elements, for example, bathrooms can be delivered to the site as prefabricated components.

“We will soon have built a thousand YIT Smartti homes. We do not begin them from scratch; good solutions can be replicated. The construction industry makes unique sites from beginning to end at the sites in vain. BIMs make it possible to standardise and prefabricate structures, accelerating the throughput times of the projects.”

3D model guides to the interiors of the future building

BIMs can be seen in action in Pasila, Helsinki, among other places. At the gigantic Tripla site, they assist in building a shopping centre, offices, apartments and a new railway station. YIT’s BIM specialist Janne Salin is also on duty there, having worked in the project for some 2.5 years.

“A large-scale construction project involves dozens of engineers. At Tripla, all plans can be included in a single 3D model,” Salin says.

Previously, technicians of each sector only read the drawings of their own specialty, and no one perceived the big picture. Employees and subcontractors still use drawings at the Tripla site, but they are available from the 3D model by clicking a button, without additional work. According to Salin, however, illustrability is the biggest asset of 3D models.

“You can never put everything in a single picture in drawings, because that would make it incomprehensible. With Building Information Model engineering and 3D models, we can really see what we are building. They help in understanding the context and the entity of which your own work will be part. Forecasting and engineering is considerably easier, and the construction workers will not face unexpected additional or demolition work.

3D models are so advanced that in addition to the overview, you can move around inside the models and look at the details. Moving is done using the same buttons as in computer games.

“Younger engineers in particular, who are used to playing games using a similar view, want to start walking inside the model right away,” Salin laughs out.

Looking to hire: digital twin

Building Information Models and other new digital solutions do not emerge from out of the blue in the construction industry, either. At YIT, the aim is to carry out all data-related projects so that their outputs can be reused, as the same data benefits also others within the company, as well as often partners.

“In recent years, we have worked hard to bring YIT to a new level in the use of data,” says Mikko Kuusakoski, who is in charge of the development of data and analytics expertise at YIT.

“Building a data-guided way of working should often be begun from understanding the customer and production processes better. These are the sectors where there is the most happening but on which we had the least data available when launching the project, for example. We initially focused on getting our own data in order to be compatible with external data. We have identified the data sets used the most within the company and begun to make them available in an easily accessible location in a cloud-based service. Everyone can easily retrieve the data they need from there.”

Conventionally, data has been collected particularly for a specific purpose. As a result, data has ended up in siloes, and cross-connecting data has been highly laborious, manual and difficult. Data has been connected using Excel, as it has been the only way to compile it.

“The idea behind data refining is in building the data resources of the company over the long term for several different purposes. In this case, setting everything up takes a little longer, but it is no longer necessary to rebuild the compatibilities afterwards,” Kuusakoski says.

He emphasises that high-quality data that supports business objectives is a requirement for all innovations in the digital era. It is the interface for the platform economy and utilisation of artificial intelligence. They are of no use if the data is not high-quality, in standard format and produced in almost real time.

At YIT, customer and production data are beginning to be in a shape that makes it possible to refine it. The ultimate objective of the project is a digital twin covering the entire company, making it possible to model the entire company and its processes. According to Kuusakoski, there is still a long way to go.

“To those who are only about to start their data journey, I have two pieces of advice: start right away and make use of the cloud. There are no shortcuts – getting your data in order and shape is the first step for everyone. Otherwise, there is no use of dreaming about the benefits of artificial intelligence, for example.”

Reporting is replaced by predictive data

Perhaps the most important of YIT’s artificial intelligence projects is associated with road maintenance. The solution, named Keliäly (Finnish for “Road weather intelligence”), has been developed for a couple of years, and it is already used on a daily basis across Finland.

“Based on data on measures and weather, for example, Keliäly provides the site manager in charge of the area with better data when making decisions – for example, whether it is necessary to spread salt on the roads, and if it is, in which order. The accuracy of Keliäly’s data has already reached a relatively good level, but the solution is still under development to become even better,” Vesa Pirinen says.

Pirinen was the head of YIT’s data administration until the start of 2018. Currently, he is in charge of strategies, new business ideas and M&As. Data also plays a key role in them.

“In paving and rock aggregate production, for example, a lot of data is already available from the asphalt and crushing stations via IoT solutions. We can remotely control the asphalt stations – a station in Norway, for example, can be turned off and on from Finland.”

Pirinen estimates that data collection and refinement will accelerate further in the near future.

“Deeper analytics will be introduced to data refining in the construction industry as well. With the role of artificial intelligence becoming more important, we will genuinely get to make use of predictive data and maximum efficiency. Data will no longer be used for conventional reporting, but genuine analysis.”

YIT will take part in the World Summit on Digital Built Environment (WBDE 2018) in Helsinki on September 11–12.

One of the Key Note speakers at the event will be Jan Gustafsson (Wednesday, September 12), Executive Vice President, Strategy and Business Development, on “Renewing construction”.

For further information, please contact:

Marko Oinas, Vice President, Strategy & Development, Housing FI & CEE, YIT Corporation, tel. +358 (0)40 506 7430, marko.oinas@yit.fi

Hanna Malmivaara, Senior Vice President, Communications, YIT Corporation, tel. +358 (0)40 561 6568, hanna.malmivaara@yit.fi

YIT is the biggest construction company in Finland and a major player in Northern Europe. We develop and build apartments, business premises and entire areas. We are also specialised in demanding infrastructure construction and paving. Together with our customers, our 10,000 professionals are creating more functional, more attractive and more sustainable cities and environments. We work in 11 countries: Finland, Russia, Scandinavia, the Baltic States, the Czech Republic, Slovakia and Poland. The new YIT was born when over 100-year-old YIT Corporation and Lemminkäinen Corporation merged on February 1, 2018. Our pro forma revenue for 2017 was over EUR 3.8 billion. YIT Corporation’s share is listed on Nasdaq Helsinki. www.yitgroup.com

Tags: