Innovative Rotating Buoyancy Modules Create Safe Buckling Zones

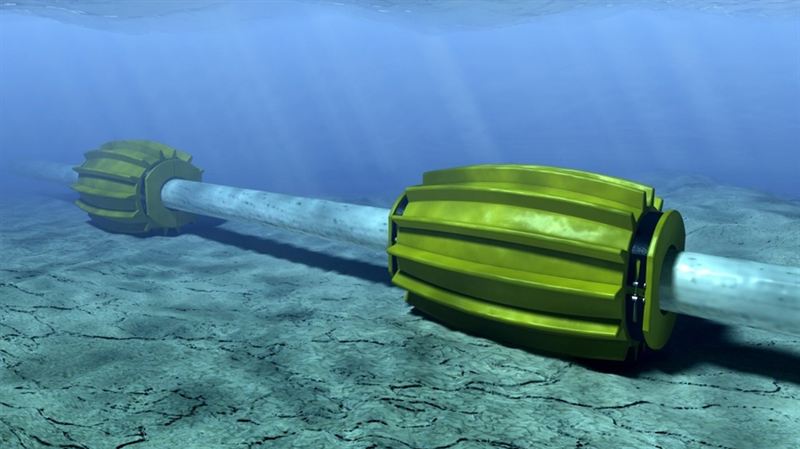

Trelleborg’s offshore operation recently developed a new Rotating Buoyancy Module system for buckling mitigation for subsea pipelines. The advanced solution is engineered to roll on the seabed to reduce lateral friction and berm creation thereby creating repeatable and predictable pipeline behavior.

Steven Bray, Oil and Gas Business Manager with Trelleborg’s offshore operation, states: “Doing business in today’s globalized markets requires a long-term approach with solutions that protect people, the environment and our customer’s investment. We are committed to improving the functionality of our products and solutions to provide wide-ranging benefits to our customers.

“With this in mind, we developed the rotating buoyancy module design to roll on the seabed to ensure predictable pipeline behavior. The modules practically eliminate rogue buckles and reduce axial walking in the pipeline. The new design reduces the quantity of modules needed to create safe buckling zones and this can lead to a significant reduction in overall project costs.”

When hot liquid flows through a pipeline, buckling typically occurs as thermal fluctuations cause the pipeline to expand and contract during start-up and shutdown sequences. This can possibly lead to problematic buckling along the length of the pipeline. While traditionally non-rotating cylindrical buoyancy modules are installed along these sections to reduce weight and friction as well as promote controlled bending, in certain conditions the modules displace seabed material. This displacement can lead to ridges or berms of earth, which start to restrict the lateral movement of the buoyancy modules.

Rotating Buoyancy Modules can be used on subsea pipelines or flowlines to reduce berm creation and create predictable, safe bucking zones. The modules practically eliminate rouge buckling and can reduce project costs for customers.

For press information or additional information on Trelleborg Offshore, contact Ruth Clay, Mobile: 1 281 740 5755; ruth.clay@trelleborg.com, @OffshoreInsight, LinkedIn.

Trelleborg’s offshore operation and Trelleborg Group

Using advanced polymer material technology, Trelleborg’s offshore operation provides high integrity solutions for the harshest and most demanding offshore environments. As part of the Trelleborg Offshore & Construction Business Area of Trelleborg Group, Trelleborg’s offshore operation specializes in the development and production of polymer and syntactic foam based seismic, marine, buoyancy, cable protection and thermal insulation products, as well as rubber-based passive and active fire protection solutions for the offshore industry. Within its portfolio are some long established and respected brands including, CRP, OCP, Viking and Emerson & Cuming. Trelleborg’s offshore operation has been providing innovative solutions to the industry for over 30 years. www.trelleborg.com/offshore

Trelleborg is a world leader in engineered polymer solutions that seal, damp and protect critical applications in demanding environments. Its innovative solutions accelerate performance for customers in a sustainable way. The Trelleborg Group has annual sales of SEK 31 billion (EUR 3.23 billion, USD 3.60 billion) and operations in about 50 countries. The Group comprises five business areas: Trelleborg Coated Systems, Trelleborg Industrial Solutions, Trelleborg Offshore & Construction, Trelleborg Sealing Solutions and Trelleborg Wheel Systems, and the operations of Rubena and Savatech. The Trelleborg share has been listed on the Stock Exchange since 1964 and is listed on Nasdaq Stockholm, Large Cap. www.trelleborg.com.

Tags: