”We will double our production of ECO dryers”

Nimo to invest 30 million SEK and expand factory with 20,000 square feet

Since the launch of Nimo’s energy efficient drying cabinets eight years ago, the production rate has gone up along with the demand in a big way. There’s a great need for high quality, energy saving drying technology in Sweden’s schools and laundry rooms, and Nimo is now investing 30 million SEK in order to fill that need.

– Drying cabinets are a necessity for most schools in Sweden and they’re used heavily all year around. The demand is so high that we need to increase our own production capacity. We’re expanding our factory in order have total control over the manufacturing process, says Timo Taiminen, MD of Nimo.

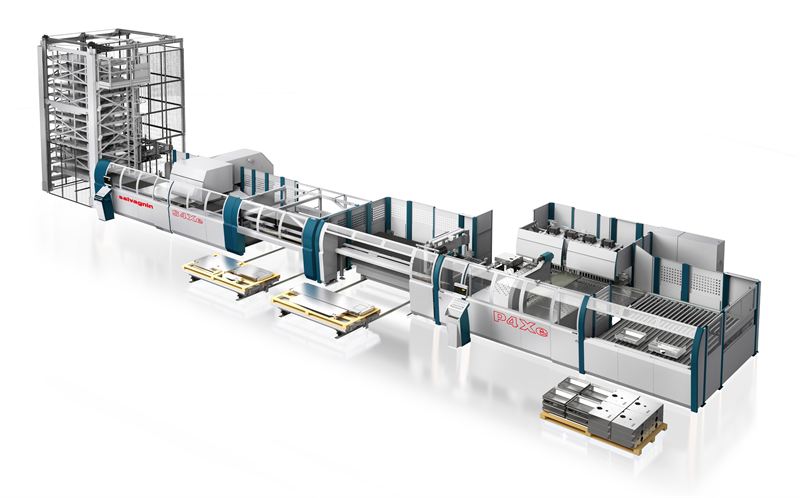

Nimo is investing 30 million SEK to expand their factory with 20,000 square feet, and to purchase a Salvagnini S4P4 manufacturing system which doubles the company’s production capacity overall.

Nimo has been providing high quality drying cabinets to Sweden for several decades. The heat pump powered ECO Dryer HP 2.0 was launched two years ago and meant a major breakthrough for the company’s new energy saving technology. After the launch, Nimo was rewarded by The Swedish Energy Agency for providing one of the most energy-efficient ways to dry clothes.

– This investment is made in order for us to grow and progress even further. The demand for our energy efficient products is at such a high level that the investment decision was an easy one to make.

The investment comprises more than 30 million SEK which will be used to expand the factory with 20,000 square feet of additional production area. The area is expected to be operational before the end of the year and will be the home of a new S4P4 bending and punching machine from Salvagnini.

– Firstly we’re creating a capacity surplus which will be filled before long due to our high production rate, and secondly we’re increasing our delivery reliability and becoming more self-sufficient. We’ll have full control over the entire manufacturing process, which in turn ensures the quality of our products even further.

– We constantly receive confirmations on our Eco Dryer 2.0 HP being a product for the future. Companies and public institutions are demanding energy-efficient, heat pump powered drying cabinets - they don’t see the products as a cost but rather as an investment. You could say we’re now investing in an energy-efficient future for all our customers, says Timo Taiminen, MD of Nimo.

For further information

Timo Taiminen, MD Nimo, 46 (0) 506-488 05, timo.taiminen@nimoverken.com

Magnus Sjöbäck, press officer Nimo, 46 (0) 70-445 15 99, magnus.sjoback@nimoverken.com

Nimo offers energy efficient drying cabinets, sinks and technical accessories for the laundry room to retailers, wholesalers and consumers in the Nordic region. The business started in 1944, has a turnover of SEK 180 million and currently employs 100 dedicated staff. Nimos factory is located in Hova, Sweden. www.nimoverken.com

Tags: