New version of PONSSE Manager improves reporting of machine chain productivity

PONSSE Manager 1.7 released

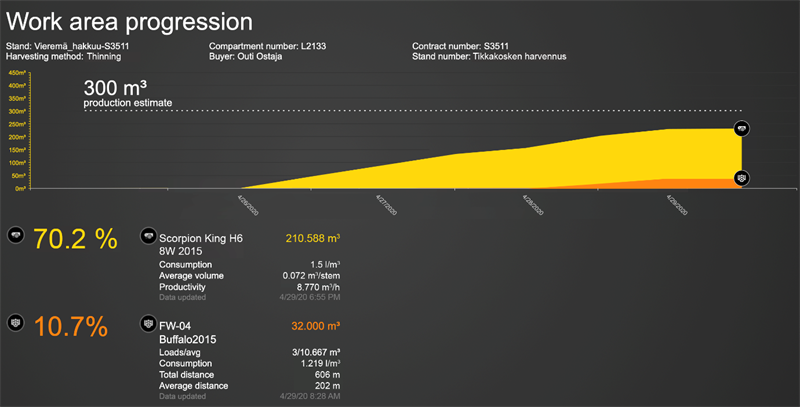

PONSSE Manager 1.7 presents forwarder production reporting, a function highly requested by customers, alongside the system’s other top features. As a new feature, PONSSE Manager displays the progress of work areas in a separate graph, showing harvester production and forwarder production relative to the total estimated volume of the work area in question.

Printable load certificate

The PONSSE Manager load certificate displays work area identification data and local transportation per storage location, both as sum totals and operator-specific values. The printable load certificate also includes the volume of each load, the assortments delivered, and the distance travelled.

“Forwarder production volumes will be updated in PONSSE Manager reports if the forwarder is equipped with a compatible PONSSE Load Optimizer loader scale or the Opti 4G operator load details feature, which allows operators to enter their roadside deliveries in the Opti 4G system. These features raise machine chain reporting to a whole new level and offer a better overview of total harvesting production”, says Juho Leskinen, Product Group Manager, information systems and digitalisation.

PONSSE Parts Online, a system for ordering spare parts, can be accessed from the PONSSE Manager main menu in countries where Parts Online service is available.

PONSSE Manager is a continuously developed data management system

To support their operations, forest machine entrepreneurs need a reliable partner to develop services that truly improve customers’ business. PONSSE Manager is a modern forest machine monitoring and data transfer system that forest machine entrepreneurs can use to see their machines’ location, productivity figures and fuel consumption, among others. With PONSSE Manager, entrepreneurs can improve the efficiency of their business and enhance productivity, thanks to real-time field operations monitoring. With Manager, entrepreneurs can monitor the progress of stands, plan and manage machine transportation, keep track of machine outputs according to assortment and print out measuring certificates. In addition, Manager informs entrepreneurs of machine maintenance needs and displays any maintenance-related notes made by the operator.

Read more: www.ponsse.com/en/web/guest/services/online-services#/

Further information

Juho Leskinen, Ponsse Plc, Product Group Manager, information systems and digitalisation, tel. +358 40 5742704, juho.leskinen@ponsse.com

Tags: