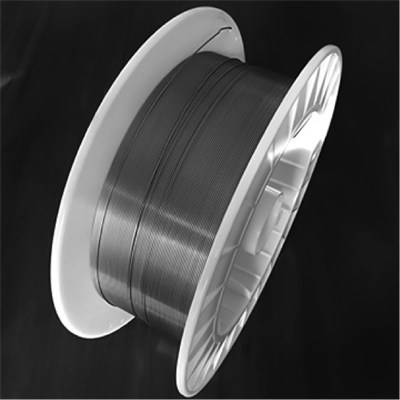

Introducing Duroxite[® ]200 WIRE for severe abrasive wear and moderate impact

Duroxite® is SSAB’s product brand for a wide range of overlay products in the form of overlay plates, overlay pipes, overlay pins and wire rolls for welding.

Duroxite overlay products are made of abrasion resistant materials deposited on top of mild steel or Hardox® wear plate to create an extremely wear resistant compound material. The latest addition to the Duroxite® family is Duroxite®200 WIRE, which is a flux-cored welding wire for hardfacing various components.

“Duroxite® 200 WIRE is mainly used for capping, routine maintenance or repair work. It can be welded on mild steel, Q&T steels, cast materials and stainless steel. Duroxite® 200 WIRE is easy to apply on site or in the workshop. A common application is capping the weld when joining complex carbide overlay plates such as Duroxite® 200 and maintaining the same service life as the plates. Duroxite® 200 WIRE is self-shielded and welded with an open-arc process using manual or machine welding”,says Lingyun Wei, product manager at SSAB.

Guaranteed wear resistance down to 75%

When welding multiple layers of Duroxite® 200 WIRE the same wear resistance is guaranteed from the surface down to 75% of the overlay thickness.

Optimal alloy formula

Duroxite® 200 WIRE forms overlay with primary chromium-rich carbides with co-existing refined multi-alloy carbides which provide a good combination of wear and impact resistance.

Examples of applications

Duroxite® 200 WIRE is designed for applications with severe abrasive wear and moderate impact up to 600°C (1100°F). Typical applications include sand and earthmoving equipment such as buckets and teeth, railway ballast tampers, dredge buckets and lips, dragline buckets, coke hammers, rippers, sizing screens, crushing equipment, brick industry components, muller tires, catalyst lift pipes, pump impellers, fan blades, rockwool rolls, wear plates operating at high temperature in the steelmaking industry.

Visit Duroxite® on the web

Find more information and technical data on Duroxite® 200 WIRE and other Duroxite® products at www.duroxite.com.

Worldwide availability

Duroxite® 200 WIRE is available from SSAB and also through Hardox Wearparts, the global network of wear service centers. Today the network includes more than 500centers in almost 100 countries. All centers can be found at www.hardoxwearparts.com/find-supplier.

Contact

Lingyun Wei, Global Product Manager Duroxite, lingyun.wei@ssab.com, phone: +1 563 209 7968

Hardox Wearparts® is a worldwide network of service centers providing wear parts and wear solutions for optimized productivity and service life. Hardox Wearparts® is a part of SSAB, the manufacturer of Hardox® wear plate.

SSAB is a Nordic and US-based steel company. SSAB offers value added products and services developed in close cooperation with its customers to create a stronger, lighter and more sustainable world. SSAB has employees in over 50 countries. SSAB has production facilities in Sweden, Finland and the US. SSAB is listed on Nasdaq Stockholm and has a secondary listing on Nasdaq Helsinki. www.ssab.com.

Join Hardox® wear plate also on social media: Facebook, Instagram, LinkedIn and YouTube.

Tags: