Premium recipe to improve product mix

SSAB aims to strengthen its position in its home markets – the Nordics and the North America. It goes hand in hand with the other strategic goal, which is to improve our product mix. But what does it actually mean, when we say we will gradually improve our product mix?

SSAB is already a highly-specialized global steel company, but we are still continuing our journey toward even more specialization. Also in the future, part of the offering will certainly consist of standard steels, but we are developing more and more special and premium products where we can deliver added customer value.

Goal for all three steel divisions

The goal of improving the product mix is relevant to all three steel divisions in SSAB, i.e. SSAB Special Steels, SSAB Europe and SSAB Americas.

SSAB Europe and SSAB Americas aim to grow their share of premium steels in sales. In SSAB Americas, investments made in slab production line technology also allow our offering of premium products to be expanded.

All the products supplied by SSAB Special Steels are by definition a “special” offering to the market, but there is still room to improve or vary the mix. SSAB Special Steels aims to grow by 35 percent and deliver 1.35 million tonnes of high-strength steels by 2020.

Today, SSAB Special Steels has a very advanced and leading portfolio, but we are pushing the boundaries with a number of niche offerings not available elsewhere on the market. These include high-end products, tooling and protection steels and, of course, the most advanced wear and structural steel grades (Hardox and Strenx).

Benefits for customers and SSAB

“We want to offer customers something they cannot get elsewhere – products in which SSAB has special capabilities. This is our way of both delivering customer value and developing the profitability of our business,” said Viktor Strömberg, Head of Strategy and Business Development.

“Our customers need and demand steel innovations, so we need to constantly improve our product performance. Of course besides offering higher customer value, these products are typically also more profitable to us,” continues Strömberg.

For example this year’s Swedish Steel Prize winner Kiruna Wagon has successfully used high-strength steels to turn it into a brand new, superior wagon solution. Kiruna Wagon’s Helix Dumper is a dumper wagon system for long-haul rail transport and efficient unloading of minerals. Use of advanced high-strength structural and wear-resistant steels made it possible to design lightweight wagons combined with a stationary Helix terminal for on-the-fly rotary unloading.

More premium products from SSAB Europe

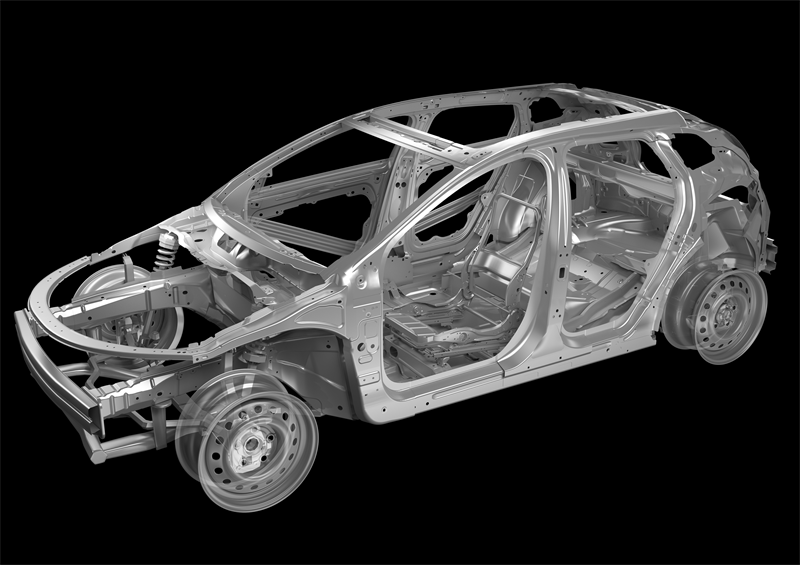

SSAB Europe aims to improve its product mix to 40 percent of premium products, compared with 30 percent in 2016. As a part of this improvement, SSAB Europe aims to deliver 750 thousand tonnes of Automotive premium products by 2020, compared to 442 thousand tonnes in 2016.

“This is a clear goal which requires a lot of work from the entire organization. The goal means switching from sales of hot-rolled coils to increasingly upgraded products. The further we are able to upgrade our products, the easier it is for our customers to operate with them. Looking ahead, we will naturally also continue to sell hot-rolled coils and this is where delivery accuracy and quality come into the sales picture,” said Olavi Huhtala head of SSAB Europe.

FACT BOX

What is premium?

The definition of premium steels is by no means a universal concept, but we in SSAB have clear lists of the products they encompass, based on, for example, performance data. In premium steels, we offer more than standard by, for example, delivering grades specifically demanded by a certain customer or grades that meet certain brand standards.

“In SSAB Europe, we have a range of branded products that offer enhanced value to our customers through tighter tolerances, improved material properties and refined composition. All of these products deliver improved performance creating a higher value in use,” said Tony Harris, VP International Sales.

“In addition, our premium products are designed to deliver sustainable environmental benefits versus standard products in the market place. For example, most of our GreenCoat products feature a Bio-based Technology (BT) coating, where a substantial portion of the traditional fossil oil has been replaced by rapeseed oil. These products offer environmental benefits in addition to increasing performance,” Harris continued.

The list goes on: Docol automotive steels are designed to combine higher strength and reduced weight for improved fuel efficiency, with best in class crash resistance to solve the challenges facing automotive OEMs.

SSAB Laser Plus with narrow and consistent dimensional tolerances has optimized surface quality for laser cutting, SSAB Boron steels are optimized for products that require complex forming in combination with high wear resistance and strength. SSAB Weathering delivers a wide range of corrosion-resistant steels.

Tags: